-

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE -

-

Phone number+86-13414362583

-

News

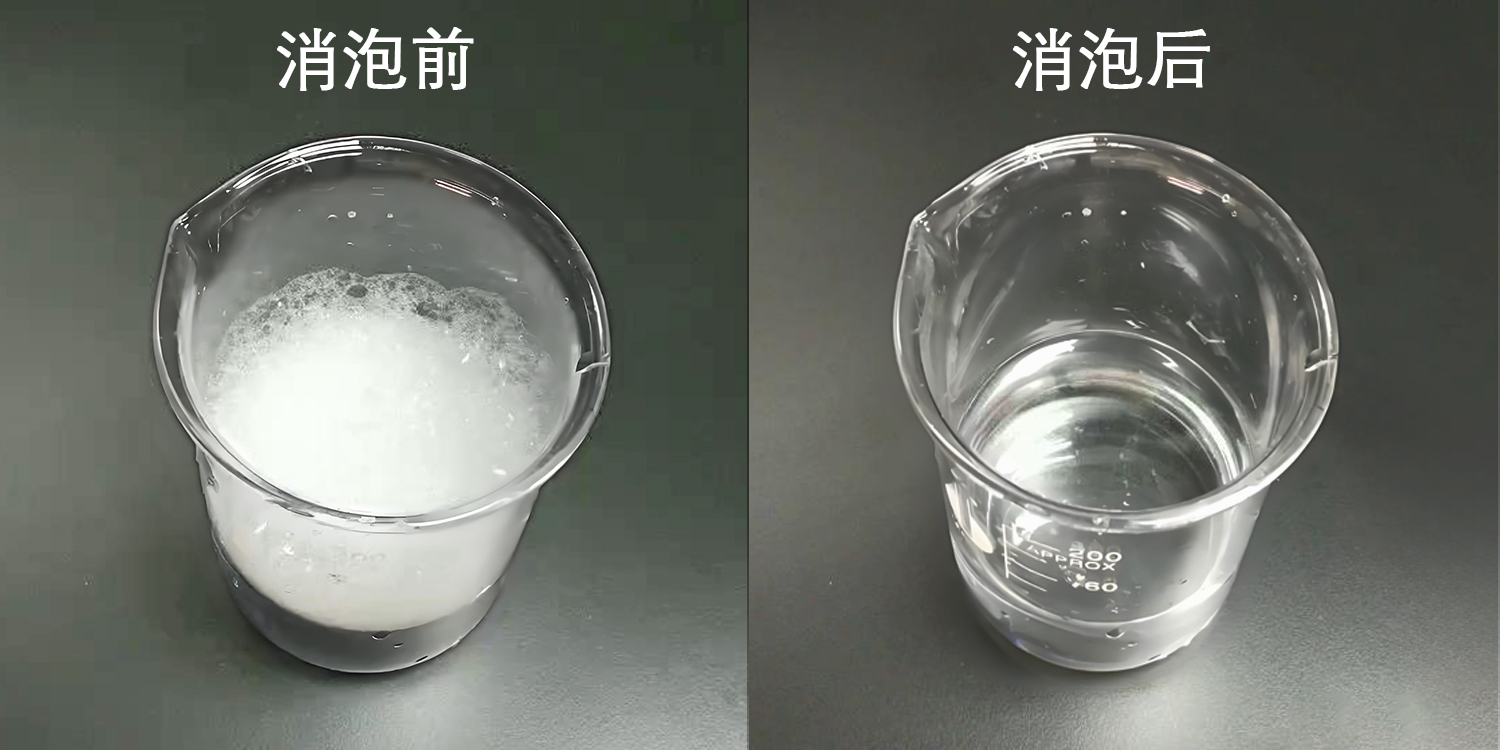

In industrial processes, wetting agents are widely used for their surface activity, but accompanying foam often hinders operational efficiency. Foam reduces mass transfer rates, causes equipment idling, or even overflow, while physical defoaming methods typically lack durability. Chemi Tech has developed specialized chemical defoamers targeting wetting agent foam, achieving rapid bubble rupture by disrupting surface tension of foam films.

1. Targeted Action: Molecular structures designed for wetting agent foam stability, enabling fast liquid film penetration;

2. Longevity: Heat/acid/alkali resistance maintains activity in harsh conditions;

3. Compatibility: Preserves wetting agent performance without secondary foaming.

For application, pilot tests are recommended to determine optimal dosage (generally 0.01%-0.5%), with direct injection into foam-rich zones or circulation systems. High-viscosity systems may require Chemi Tech oil-based defoamers, while silicone-modified variants suit aqueous systems.

Maintenance tips: Store in cool environments, stir before use. Re-evaluate defoamer selection if foam conditions change. Chemi Tech's technical team provides customized foam analysis services.

Guangzhou Chemi Tech New Material Co., Ltd.

Address : No. 3 Road, Lanshan Village, Xiancun Town, Zengcheng District, Guangzhou City

Contact : +86-19820415595(Manager Fang)

Tel : +86-13414362583(Manager Lee)

E-mail : crystal@gzchemitech.com