-

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE -

-

Phone number+86-13414362583

-

News

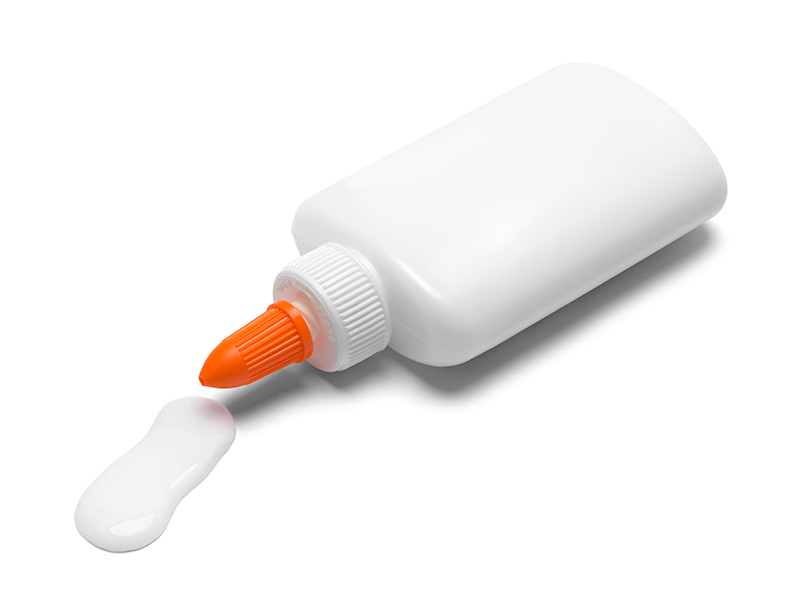

In adhesive production and application, the choice of defoamer critically impacts product quality. Mismatched defoamers may lead to bubble retention, uneven curing, or reduced bond strength, compromising end-product reliability.

Key Issues Explained

1. Bubble Retention: Inefficient defoamers fail to eliminate bubbles generated during mixing or filling, causing voids in adhesive layers and weakening mechanical properties.

2. Poor Compatibility: Some defoamers react with adhesive formulations, causing stratification or craters, affecting appearance and coating uniformity.

3. Short-Term Efficacy: Defoamers degrading under high temperatures or prolonged storage allow bubble reformation, leading to batch inconsistencies.

Chemi Tech's Approach

Chemi Tech develops specialized defoamers for adhesives with:

- Rapid Bubble Breaking: Molecular structures optimized for adhesive viscosity to remove micron-sized bubbles instantly.

- Long-Term Stability: Continuous action during curing prevents post-process bubble regeneration.

- Broad Compatibility: Suitable for epoxy, polyurethane, and other adhesive systems.

Lab tests and case studies confirm Chemi Tech defoamers enhance adhesive yield and performance consistency. Users should select models based on specific formulations and processes to mitigate risks.

Guangzhou Chemi Tech New Material Co., Ltd.

Address : No. 3 Road, Lanshan Village, Xiancun Town, Zengcheng District, Guangzhou City

Contact : +86-19820415595(Manager Fang)

Tel : +86-13414362583(Manager Lee)

E-mail : crystal@gzchemitech.com