-

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE -

-

Phone number+86-13414362583

-

News

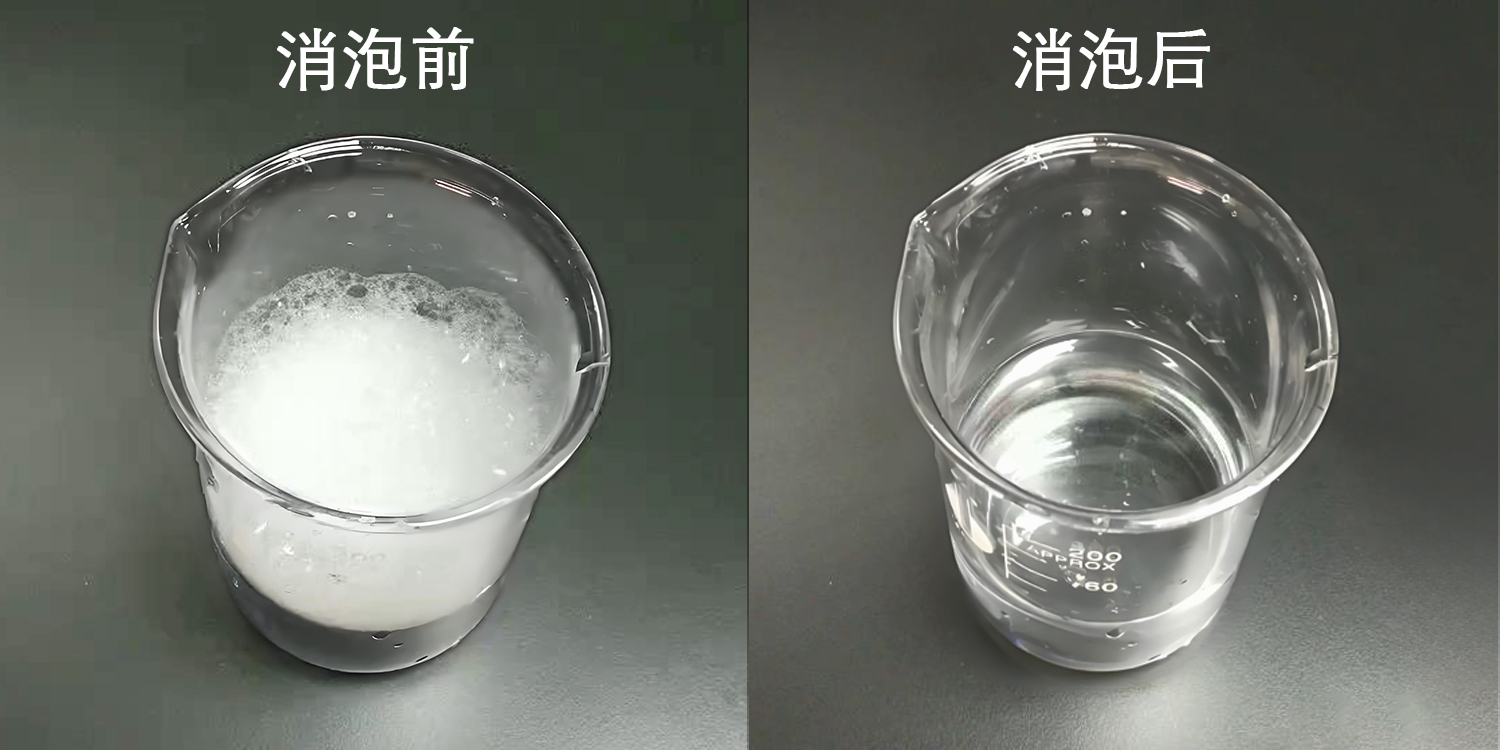

In industrial production, defoamers are critical materials for resolving foam issues, with their types and performance directly impacting process efficiency. Below are common industrial defoamer categories and their technical characteristics:

Utilizing polydimethylsiloxane (PDMS) as the core component, these defoamers exhibit extremely low surface tension and are suitable for high-temperature, high-shear environments. Chemi Tech's acid-alkali-resistant silicone defoamers, for instance, operate stably within pH 2-14 and achieve rapid dispersion through specialized emulsification techniques.

Combining the advantages of silicone and polyether chains, these products retain rapid foam-breaking capabilities while offering long-lasting foam suppression. Chemi Tech optimizes molecular structures to minimize oil shrinkage in resin emulsions and water-based coatings, with dosage as low as 0.1%-1.0%.

Based on nonionic amide wax, these are ideal for systems sensitive to silicone residues. Chemi Tech's non-silicone variants maintain stability at 5°C-35°C through composite emulsification and are compatible with high-viscosity fluids.

Chemi Tech defoamers employ customized formulations to meet diverse industrial needs. For example, models designed for wastewater treatment maintain efficiency under thermal cycling and recommend precise dosing via metering pumps to avoid overuse.

Guangzhou Chemi Tech New Material Co., Ltd.

Address : No. 3 Road, Lanshan Village, Xiancun Town, Zengcheng District, Guangzhou City

Contact : +86-19820415595(Manager Fang)

Tel : +86-13414362583(Manager Lee)

E-mail : crystal@gzchemitech.com