-

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE -

-

Phone number+86-13414362583

-

News

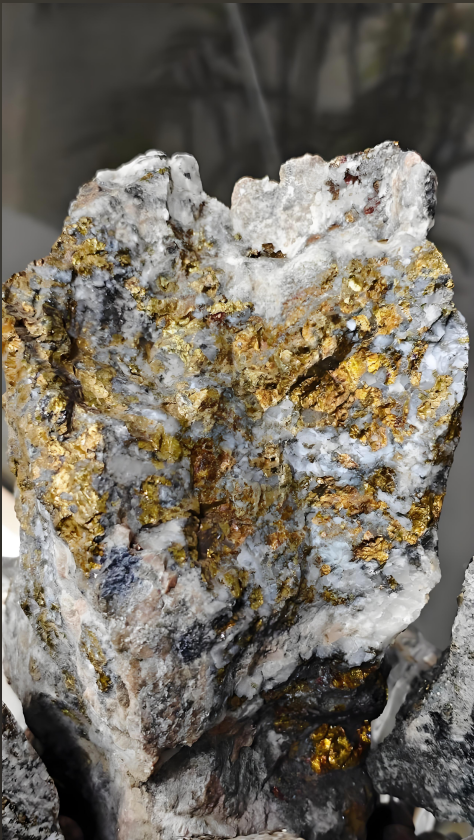

Scientific defoamer application is crucial for continuous and cost-effective precious metal flotation. Chemi Tech's systematic solutions cover the entire flotation process, enabling precise control.

Adding defoamers (0.05%-0.1% concentration) during pulp conditioning reduces stable foam from fine particles and residual reagents, ensuring uniform feed. Monitor pH and temperature for optimal dispersion.

Automated dosing systems inject defoamers into different cell zones. For example, use low doses in roughing for suppression and higher doses in cleaning to prevent overflow. Adjust dosing based on real-time froth thickness (3-5cm).

Spray systems with Chemi Tech defoamers eliminate surface foam in tailings ponds, minimizing metal loss and pump cavitation.

Dosage:5-15g/t ore, adjusted by ore type (sulfide/oxide).

Dilution: ≤1:10 with hard water; avoid prolonged settling.

Mixing: High-speed agitation (≥1200rpm) ensures uniform dispersion.

Chemi Tech offers customized solutions through lab simulations and on-site trials, enhancing process stability and equipment longevity.

Guangzhou Chemi Tech New Material Co., Ltd.

Address : No. 3 Road, Lanshan Village, Xiancun Town, Zengcheng District, Guangzhou City

Contact : +86-19820415595(Manager Fang)

Tel : +86-13414362583(Manager Lee)

E-mail : crystal@gzchemitech.com