-

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE -

-

Phone number+86-13414362583

-

News

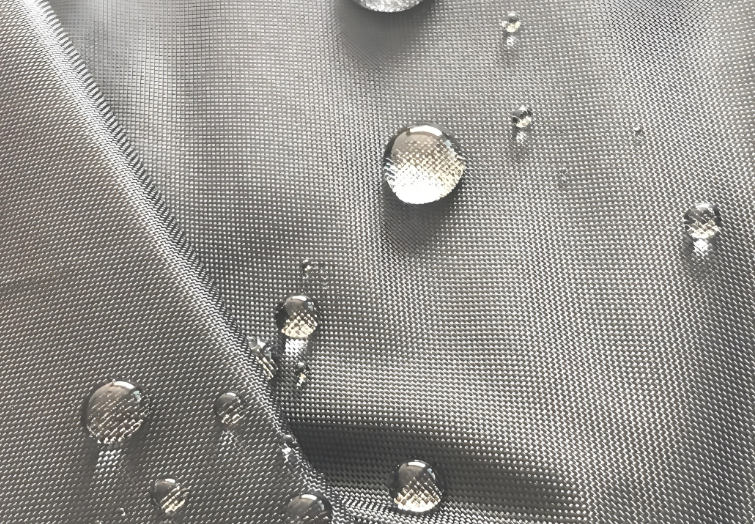

In the laboratory of a large dyeing factory in Zhejiang, Technical Supervisor Li was staring anxiously at a vat of dye liquor. While the newly purchased high-efficiency penetrant significantly improved dye penetration, the continuous foam formation on the surface kept forcing production line shutdowns. This seemingly simple contradiction actually represents a longstanding technical challenge in the industry: how to control foam without compromising penetration effectiveness?

Through in-depth research, Chemi Tech's R&D team discovered that hydrophobic particles in conventional defoamers compete with penetrant molecules for adsorption sites on fabric surfaces, reducing penetration efficiency by 20-30%. After technical breakthroughs, we developed a specialized penetrant defoamer featuring:

• Selective defoaming: Acts exclusively on gas-liquid interface films without interfering with penetrant spreading on fabrics

• Dynamic equilibrium: Automatically adjusts active substance release rate based on foam volume

• Temperature-responsive: Maintains optimal defoaming performance within 40-80℃ working range

Field application data demonstrates:

• 3x faster foam elimination with 15% reduction in penetration time

• Fabric capillary effect maintained at ≥10cm/30min

• Defoamer residue <0.2ppm, fully compliant with export standards

"Now we no longer have to choose between penetration and defoaming performance," shared Supervisor Li during the quarterly review meeting. "Our first-pass dyeing qualification rate has improved from 88% to 96.5%."

At Chemi Tech, we firmly believe that true technological breakthroughs lie in achieving perfect synergy between seemingly conflicting factors.

Guangzhou Chemi Tech New Material Co., Ltd.

Address : No. 3 Road, Lanshan Village, Xiancun Town, Zengcheng District, Guangzhou City

Contact : +86-19820415595(Manager Fang)

Tel : +86-13414362583(Manager Lee)

E-mail : crystal@gzchemitech.com