-

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE -

-

Phone number+86-13414362583

-

News

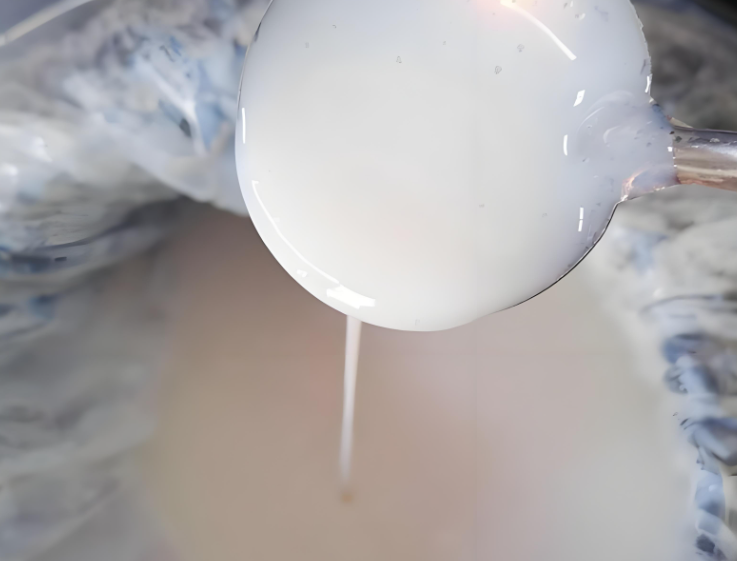

In coating applications, leveling performance directly affects the final appearance and properties of the film. Many manufacturers face surface defects such as orange peel, brush marks, and craters, leading to high rework rates, increased costs, and reduced product value. Addressing these challenges, Chemi Tech has developed high-performance leveling agents and tailored solutions based on years of technical expertise.

Common issues include poor flow properties, uneven surface tension, and foam control difficulties, often caused by formulation design, material compatibility, or application processes. Chemi Tech leveling agents optimize viscosity and surface tension to promote even coating distribution and eliminate irregular textures quickly.

The solution involves four steps: First, analyze the substrate and coating type to select the appropriate leveling agent series; second, conduct lab tests to determine dosage and mixing methods; third, adjust application parameters such as humidity, temperature, and spray pressure; finally, establish standardized procedures for consistent quality.

A manufacturer applying industrial coatings on metal components experienced severe orange peel texture, with low gloss and rough surface. By using Chemi Tech silicone-based leveling agent KMP-208 at 0.3% dosage and adjusting curing temperature, surface smoothness improved significantly. Gloss reached over 90%, first-pass acceptance rate increased to 98%, and grinding/recoating steps were reduced.

Chemi Tech leveling agents offer excellent compatibility, low dosage, and durable effects, suitable for industrial, wood, and plastic coatings. We provide free technical support and samples to help customers achieve coating quality upgrades.

Guangzhou Chemi Tech New Material Co., Ltd.

Address : No. 3 Road, Lanshan Village, Xiancun Town, Zengcheng District, Guangzhou City

Contact : +86-19820415595(Manager Fang)

Tel : +86-13414362583(Manager Lee)

E-mail : crystal@gzchemitech.com