-

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE -

-

Phone number+86-13414362583

-

News

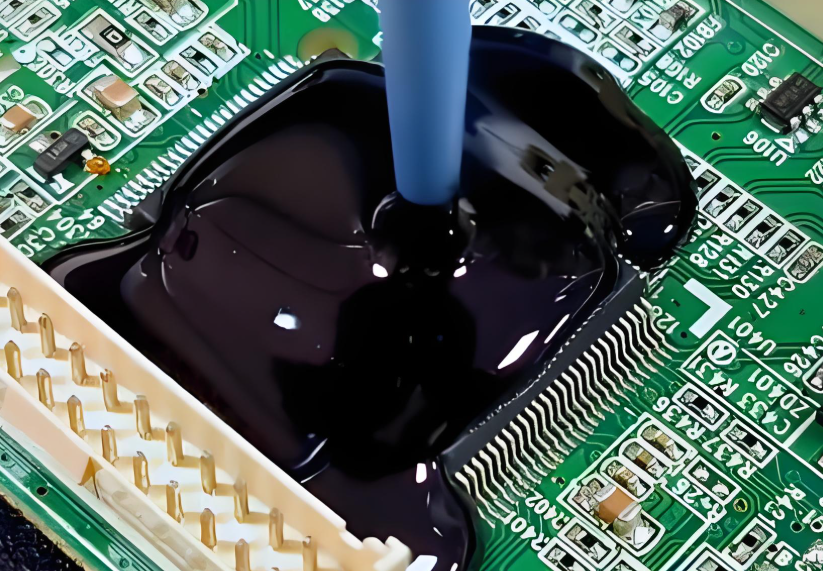

Bubble formation in encapsulation adhesive processes remains a persistent challenge for manufacturers. These bubbles compromise not only the visual integrity of encapsulated components but also may lead to reduced performance reliability and potential failures in later usage. Traditional methods such as natural settling or vacuum degassing often prove inefficient for large-scale production.

To address this issue, Chemi Tech has developed a high-performance defoamer series specifically designed for encapsulation adhesives. With its unique molecular structure, it rapidly breaks bubble surface tension and suppresses foam regeneration. It is compatible with various adhesive systems including epoxy, silicone, and polyurethane. The product requires no changes to existing production lines—simply add it during mixing in recommended ratios to achieve fast bubble elimination.

One electronic component manufacturer previously struggled with high bubble retention rates during encapsulation, leading to inconsistent insulation performance. After adopting Chemi Tech's defoamer, a three-step solution was implemented: first, material compatibility testing to determine the optimal dosage; second, optimization of mixing parameters to prevent secondary bubble formation; and finally, cross-section analysis confirming bubble rates below 0.5%. The manufacturer achieved consistent quality across three consecutive batches with a 20% increase in production efficiency.

Chemi Tech's defoamers have helped numerous enterprises improve product consistency and manufacturing throughput. We offer free sample testing and technical support to ensure effective solutions. If you are facing bubble-related issues in encapsulation, contact us for a tailored approach.

Guangzhou Chemi Tech New Material Co., Ltd.

Address : No. 3 Road, Lanshan Village, Xiancun Town, Zengcheng District, Guangzhou City

Contact : +86-19820415595(Manager Fang)

Tel : +86-13414362583(Manager Lee)

E-mail : crystal@gzchemitech.com