-

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE -

-

Phone number+86-13414362583

-

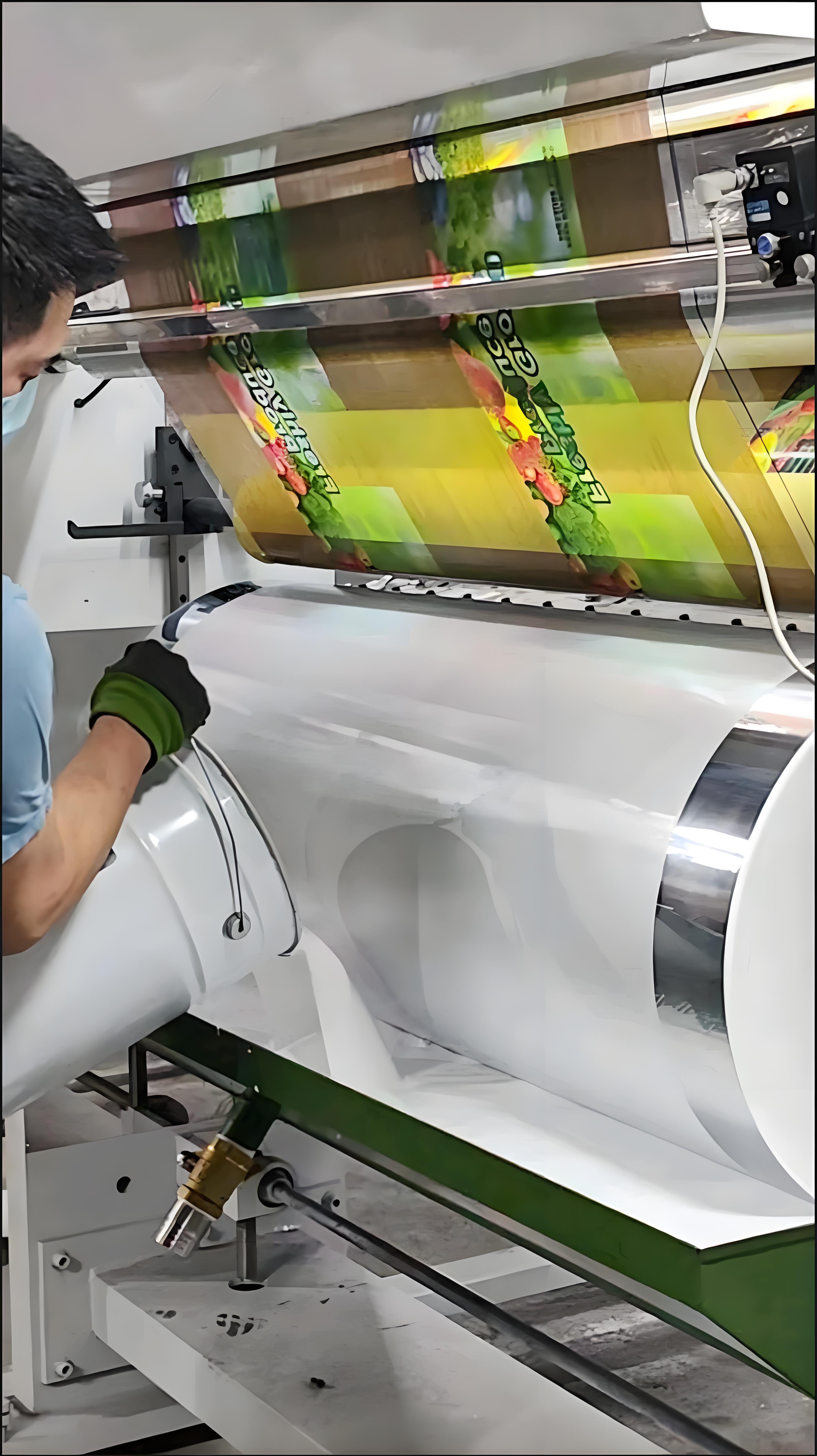

Foam formation in gravure printing inks is a persistent challenge that compromises print quality and production efficiency. Bubbles may cause surface defects such as white spots, broken lines, or uneven coloration, often requiring operational downtime. To address this, Chemi Tech has developed advanced defoamers tailored for gravure ink systems, capable of rapidly eliminating existing foam and preventing its recurrence.

The key advantage of Chemi Tech defoamers lies in their unique chemical composition, which penetrates foam surfaces swiftly, reduces ink surface tension, and accelerates bubble collapse. With low dosage requirements, these defoamers maintain optimal ink viscosity, adhesion, and color performance. They also exhibit excellent compatibility with both solvent-based and water-based gravure ink formulations.

1. Rapid Action: Over 90% foam reduction within 5 minutes under high-speed press conditions.

2. Long-lasting Effect: Sustained foam suppression minimizes mid-process reapplication.

3. Robust Stability: Resistance to high temperatures and shear forces suits complex gravure printing environments.

For industries demanding high-precision printing (e.g., packaging, labels), Chemi Tech defoamers effectively reduce defect rates and optimize equipment utilization. Users are advised to select appropriate product variants based on ink formulations and conduct small-scale trials to determine optimal dosing.

Guangzhou Chemi Tech New Material Co., Ltd.

Address : No. 3 Road, Lanshan Village, Xiancun Town, Zengcheng District, Guangzhou City

Contact : +86-19820415595(Manager Fang)

Tel : +86-13414362583(Manager Lee)

E-mail : crystal@gzchemitech.com