-

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE -

-

Phone number+86-13414362583

-

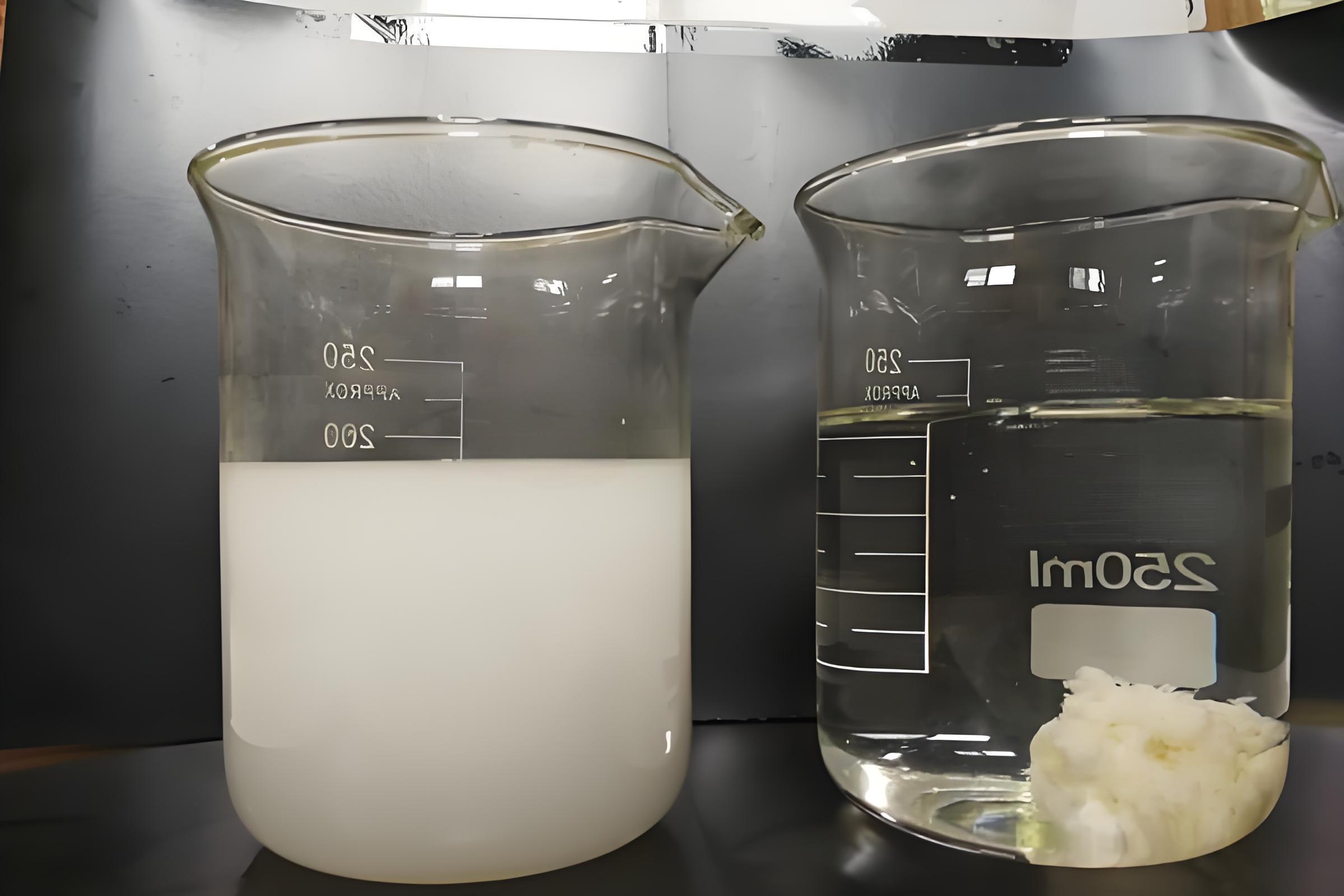

The efficacy of demulsifiers in industrial water treatment hinges on dosing methods, system compatibility, and environmental stability. Key strategies for Chemi Tech demulsifiers include:

Settling Tanks: Use slow-acting demulsifiers (e.g., high-MW polyethers) for sufficient contact time;

Rapid Separation: Inject fast-acting types (e.g., low-MW quaternary salts) at pipeline mixers or electric dehydrator inlets;

Physical Enhancement: Combine with air flotation or centrifugation to accelerate oil rise and solid settling.

High-Salinity Adaptation: Sulfonated asphalt derivatives maintain efficacy in Cl >5000 mg/L environments;

Sludge Control: Reduce demulsifier dosage to 0.005%-0.02% when compounding with inorganic flocculants (e.g., PAC) to minimize sludge volume.

Temperature Tolerance: Mineral-oil products remain stable at 5°C-50°C without crystallization or degradation;

Storage Management: Emulsion types require mechanical stirring to redisperse settled active components;

Longevity: Modified silicone polyethers provide 24-hour sustained demulsification, reducing dosing frequency by 30%.

Process coordination (e.g., pH adjustment to 6-9 for optimal interfacial activity) and real-time monitoring (e.g., >90% clarified water transmittance) significantly enhance operational efficiency. Feel free to contact via +8619820415595.

Guangzhou Chemi Tech New Material Co., Ltd.

Address : No. 3 Road, Lanshan Village, Xiancun Town, Zengcheng District, Guangzhou City

Contact : +86-19820415595(Manager Fang)

Tel : +86-13414362583(Manager Lee)

E-mail : crystal@gzchemitech.com