-

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE -

-

Phone number+86-13414362583

-

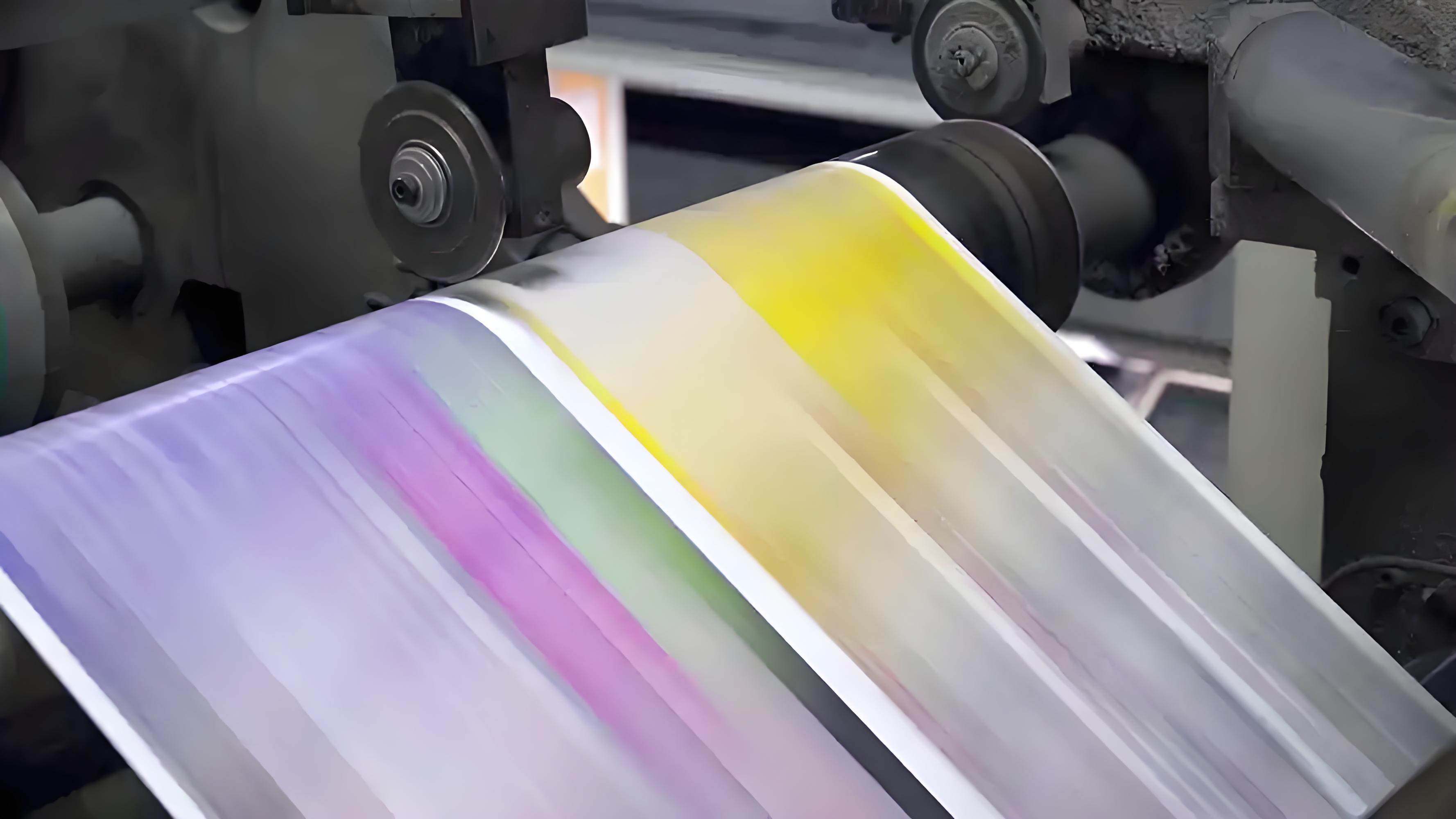

In PVC card printing, surface smudging and scratching are common quality defects. During the output process, friction between cards and scrapers often damages the ink layer, reducing visual quality and durability. Traditional methods like adjusting ink viscosity (adding reducers) or reducing pressure offer only temporary relief but fail to eliminate micro-scratches.

Chemi Tech's KMB-251 Anti-Scuff Surface Treatment enhances ink layer durability through film-forming technology. It creates a nano-protective layer after ink curing, significantly increasing surface abrasion resistance. Key technologies include:

Cross-linking Reinforcement: Modified siloxane components cross-link with ink resins to densify the coating;

Friction Reduction: Micron-scale wax particles lower surface friction coefficient, minimizing scraper damage.

A client producing PVC membership cards via UV offset printing experienced 15% scratch defects on card backs due to scraper contact. Conventional solutions required frequent stopping producing for cleaning, and wasting over 100 meters of material daily.

After adopting KMB-251:

Added at 3% to overprint varnish without equipment modifications;

Scratch defect rate dropped below 1.5%, scraper cleaning cycles extended 4 times;

Daily productivity increased by 22% due to reduced stopping time 39 minutes.

This solution suits high-speed offset and gravure printing, compatible with both aqueous and UV inks. Chemi Tech delivers lasting physical protection for glossy prints through surface performance optimization.

Guangzhou Chemi Tech New Material Co., Ltd.

Address : No. 3 Road, Lanshan Village, Xiancun Town, Zengcheng District, Guangzhou City

Contact : +86-19820415595(Manager Fang)

Tel : +86-13414362583(Manager Lee)

E-mail : crystal@gzchemitech.com