-

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE -

-

Phone number+86-13414362583

-

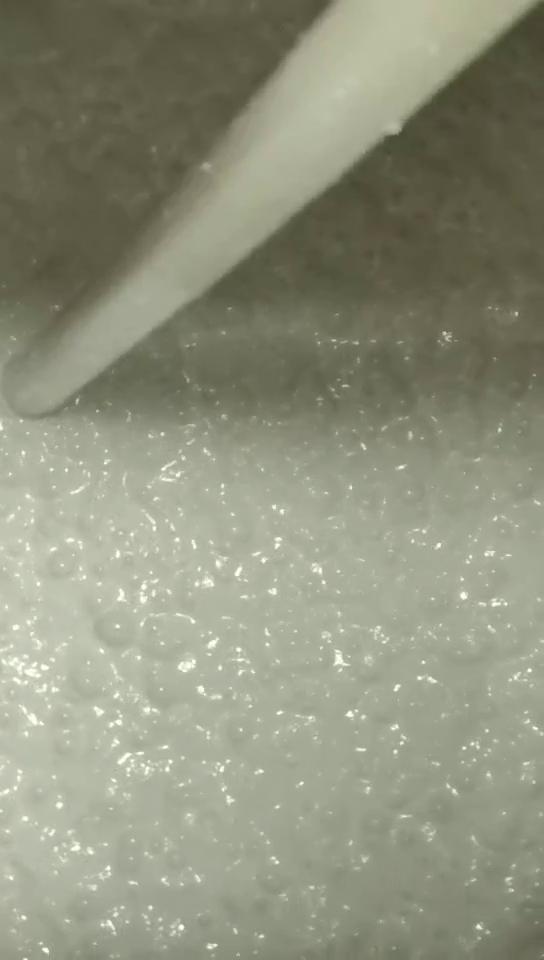

In the composite material workshop, Chief Engineer Zhang frowned at the freshly demolded carbon fiber component - its surface was riddled with tiny pinholes, like the moon struck by micro meteorites. "Foam strikes again," he sighed. This scenario repeats daily in resin processing plants worldwide. Chemi Tech engineers knew solving this industry headache required reinventing defoamers.

During vacuum infusion or high-temperature curing, trapped bubbles become time bombs. They not only mar surface finish but compromise mechanical properties. In wind turbine blade production, 1% porosity can reduce fatigue resistance by 15%; in electronic packaging, a single micron-sized bubble may scrap a $10,000 chip.

Conventional defoamers often fail resin systems: some decompose at 180°C, others interfere with curing. Worse, many suppress foam temporarily while creating hidden micro-defects.

In Chemi Tech labs, Dr. Wang's team developed "smart-targeting" resin defoamers. These molecules work like precision-guided missiles, selectively attacking bubble interfaces without disrupting resin crosslinking.

Test data from an aerospace composite plant was remarkable: porosity in carbon fiber prepreg dropped from 1.2% to 0.3%, with 18% improved interlaminar shear strength. "This isn't just a defoamer - it's a performance enhancer," the chief engineer noted in the acceptance report.

In Chemi Tech's accelerated aging lab, new defoamers undergo 500th thermal cycle testing. The CTO pointed at monitors: "We ensure clients' products maintain peak performance a decade later." This meticulous approach explains Chemi Tech's industry leadership - perfecting every technical detail.

Guangzhou Chemi Tech New Material Co., Ltd.

Address : No. 3 Road, Lanshan Village, Xiancun Town, Zengcheng District, Guangzhou City

Contact : +86-19820415595(Manager Fang)

Tel : +86-13414362583(Manager Lee)

E-mail : crystal@gzchemitech.com