-

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE -

-

Phone number+86-13414362583

-

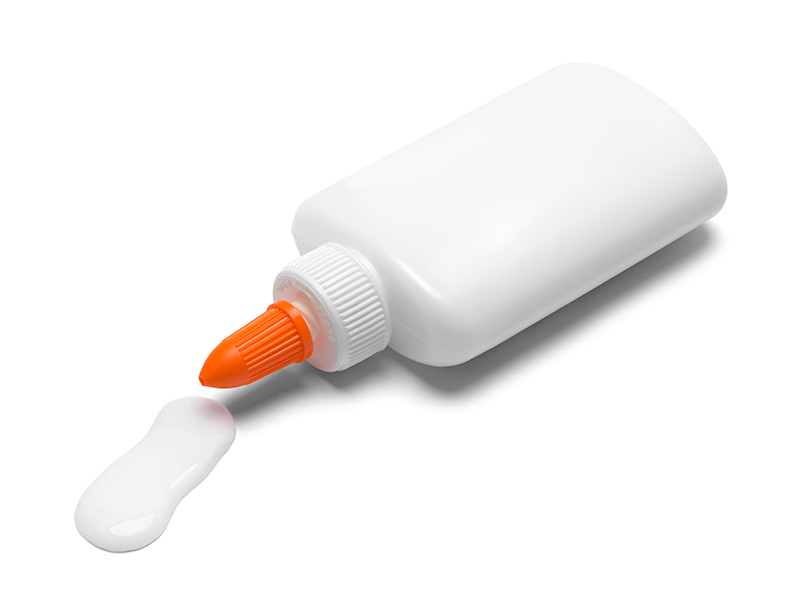

At an adhesive manufacturing facility, engineers were battling persistent foam formation during high-speed mixing and filling processes. These stubborn bubbles caused inaccurate filling volumes and created voids in finished products, severely impacting performance and appearance.

The production manager tried various remedies:

1、Reducing mixing speed

2、Extending settling time

3、Adjusting surfactant formulas

But results were limited - production efficiency dropped 15% while customer complaints continued to rise.

After implementing Chemi Tech Adhesive Defoamer, the problems were completely resolved. Key features include:

1、Rapid foam collapse within 30 seconds by penetrating bubble films

2、Excellent compatibility with various resin systems, no effect on bonding performance

3、High temperature resistance for different process conditions

"Our filling accuracy improved to 99.5% and product pass rate exceeded 98%," said QC Supervisor Li. "Most importantly, we regained full production line speed."

1、Tailored Formulations: Specific solutions for acrylic, PU, epoxy and other adhesive systems

2、Long-lasting Stability: No re-foaming issues during storage

3、Easy Application: Direct addition without process changes

4、Cost-effective: Only 0.1-0.3% dosage required for optimal results

The technical director noted: "Chemi Tech defoamer solved our long-standing quality issues, significantly enhancing our products' market competitiveness."

Guangzhou Chemi Tech New Material Co., Ltd.

Address : No. 3 Road, Lanshan Village, Xiancun Town, Zengcheng District, Guangzhou City

Contact : +86-19820415595(Manager Fang)

Tel : +86-13414362583(Manager Lee)

E-mail : crystal@gzchemitech.com