-

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE -

-

Phone number+86-13414362583

-

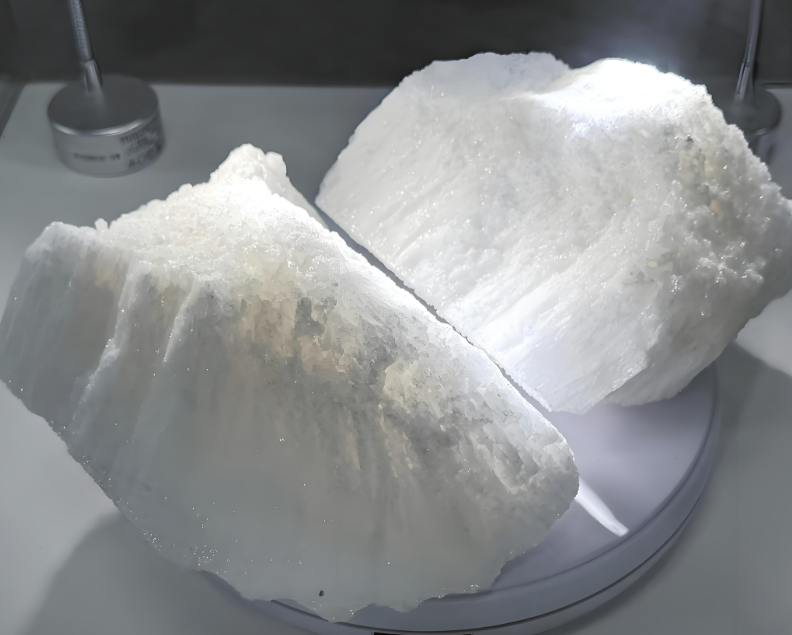

At an alumina production plant in Jincheng, Shanxi, process engineer Master Zhao was facing a persistent production challenge: the stubborn foam generated in the decomposition process not only affected the settling rate but also reduced the efficiency of subsequent filtration. These foams acted like an invisible barrier, hindering smooth production.

"Every time I saw those foams, it was like watching the production line 'hiccup'," Master Zhao recalled. "We tried adjusting process parameters and switching defoamers, but nothing worked well."

The breakthrough came with a visit from Chemi Tech's technical team. After on-site inspection, they recommended the KM-300 defoamer specifically developed for alumina production. The results were impressive:

1、Foam layer thickness reduced by 80% within 2 minutes"It's like installing a 'defoaming switch' for the production line," Master Zhao said. "Now we don't have to work overtime for foam problems anymore."

"We don't just sell products, we provide solutions," said Engineer Wang from Chemi Tech. Currently, this defoamer has been verified in multiple alumina production plants, becoming a "secret weapon" for stable production.

Guangzhou Chemi Tech New Material Co., Ltd.

Address : No. 3 Road, Lanshan Village, Xiancun Town, Zengcheng District, Guangzhou City

Contact : +86-19820415595(Manager Fang)

Tel : +86-13414362583(Manager Lee)

E-mail : crystal@gzchemitech.com