-

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE -

-

Phone number+86-13414362583

-

In a bustling metalworking workshop in the South, Engineer Li, a seasoned professional, frowned deeply. A batch of precision metal components awaited their crucial rust preventive oil bath. However, the oil sump's surface was churning with thick, viscous foam – an unwelcome guest stubbornly clinging on. This foam not only obscured visibility but, more critically, acted like an invisible barrier, preventing the rust preventive oil from making full contact with the metal surfaces. Engineer Li knew the implications all too well – localized thinning or even absence of the protective film, allowing the insidious threat of corrosion to take root unseen. Time was ticking, and the protective efficacy for the parts was being eroded by the foam.

Traditional methods like stirring or settling proved ineffective. This foam, born from surfactant accumulation, mechanical agitation, or contamination, possessed an unusually stable structure, resistant to ordinary physical interventions. Finding a solution that could precisely 'target' the foam without compromising the core properties of the rust preventive oil became imperative.

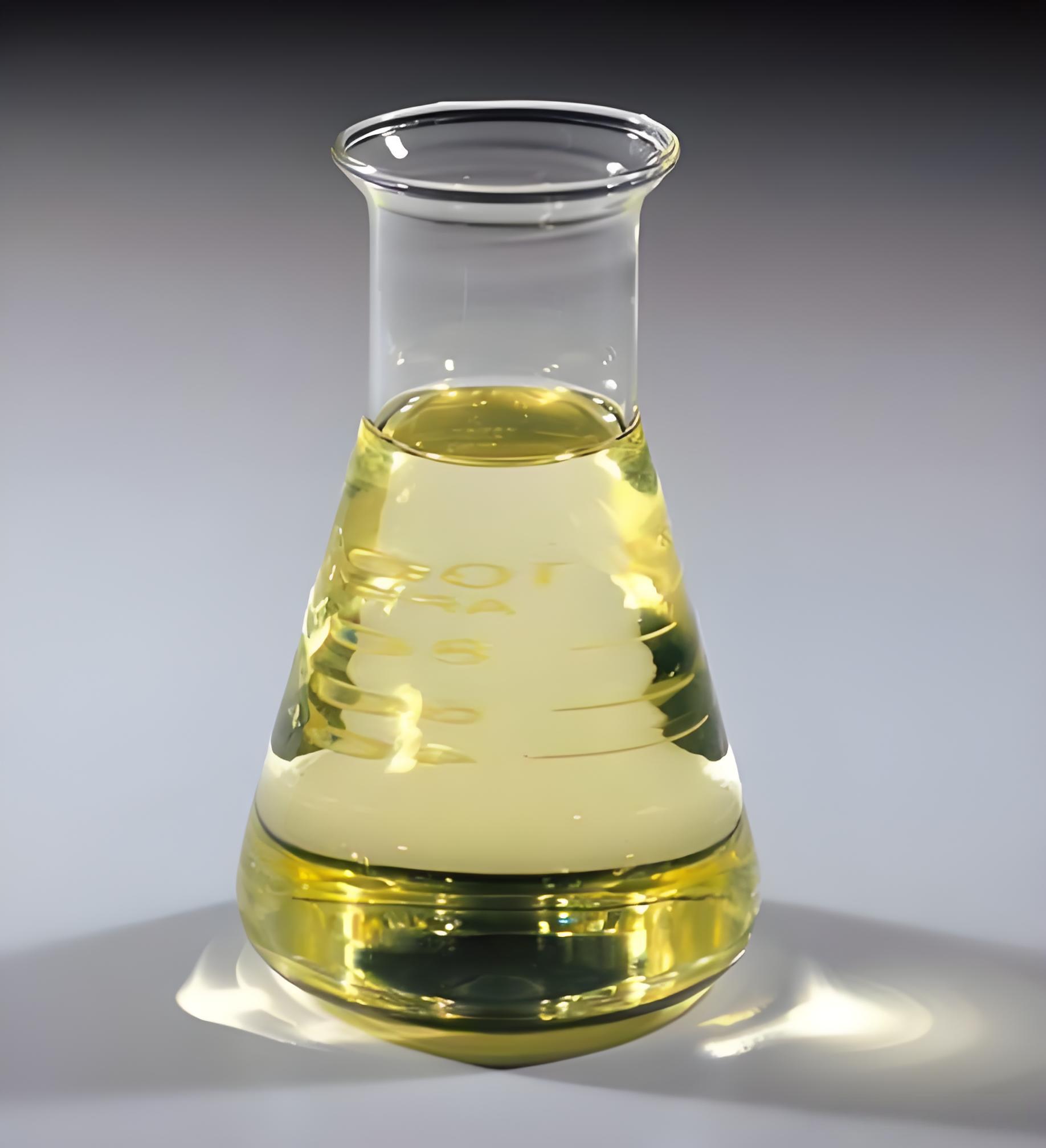

This is where Chemi Tech's specialized Defoamer for Rust Preventive Oil demonstrates its value. We delve deep into the unique composition of rust preventive systems and the complex mechanisms of foam generation. Chemi Tech's defoamer is not merely 'bubble-popping liquid'; it's a specialty chemical meticulously engineered for oily media. At its core are selected modified polysiloxanes and highly effective active ingredients, characterized by extremely low surface tension. Upon addition to the oil sump, it rapidly penetrates the fragile air-liquid interfacial film of the bubbles. Like a precise 'demolition expert', it instantly disrupts the foam structure, achieving rapid bubble breaking.

Crucially, it disperses effectively within the oil for long-lasting performance, continuously suppressing the formation of new foam. This ensures that throughout the coating, draining, and even subsequent storage stages, foam struggles to re-emerge. The rust preventive oil can then uniformly and completely envelop every metal component, forming a dense, uninterrupted protective layer that truly isolates the metal from air and moisture. Feedback from Engineer Li's workshop confirmed the foam nuisance was resolved, rust prevention significantly enhanced, and oil wastage due to foam dramatically reduced.

Choosing Chemi Tech means infusing your rust preventive process with the power of 'tranquility'. Bid farewell to foam disturbances and let your metals rest securely under reliable protection as time passes. Contact Chemi Tech today for your tailored rust preventive oil defoaming solution!

Guangzhou Chemi Tech New Material Co., Ltd.

Address : No. 3 Road, Lanshan Village, Xiancun Town, Zengcheng District, Guangzhou City

Contact : +86-19820415595(Manager Fang)

Tel : +86-13414362583(Manager Lee)

E-mail : crystal@gzchemitech.com