-

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE -

-

Phone number+86-13414362583

-

In a bustling daily chemical production plant, machines hummed as they packed bags of soap powder into storage. Yet months earlier, engineers grappled with a persistent challenge: whenever active ingredients in the formula reacted vigorously, foam would surge uncontrollably, breaching container limits like stubborn wild horses. This not slowed production but also compromised product consistency.

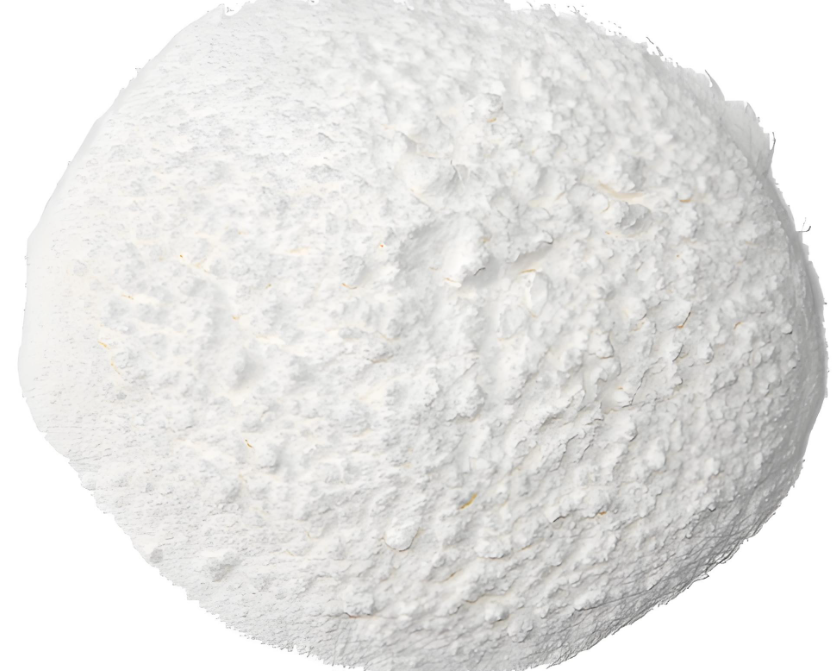

The turning point arrived when a deep gray liquid additive from Chemi Tech was introduced into the trial line. Specifically designed for soap powder, this defoamer leveraged a unique composite technology of polymer structures and hydrophobic particles. Instead of brutally destroying foam, it acted as an experienced mediator—embedding into bubble membranes upon formation, reducing surface tension and destabilizing films to collapse foam instantly while inhibiting regeneration. After 72 hours of continuous testing, foam levels dropped consistently to below 5% of original readings, without compromising cleaning power or solubility.

Beyond expectations, the defoamer demonstrated remarkable adaptability across varying water hardness and temperature conditions. Whether in alkaline environments of hard water regions or under high-temperature agitation, its micron-sized particles dispersed uniformly within the formula, functioning as a silent guardian. Production line efficiency increased by 20%, while additive costs per ton decreased.

Chemi Tech’s team holds a firm belief: true industrial innovation lies in mastering details. When foam recedes, it leaves not only clean machinery and stable products but also a profound testament to the chemistry of precision control.

Guangzhou Chemi Tech New Material Co., Ltd.

Address : No. 3 Road, Lanshan Village, Xiancun Town, Zengcheng District, Guangzhou City

Contact : +86-19820415595(Manager Fang)

Tel : +86-13414362583(Manager Lee)

E-mail : crystal@gzchemitech.com