-

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE -

-

Phone number+86-13414362583

-

In the bustling workshop of adhesive production, Engineer Li frowned once again. A newly produced batch of starch adhesive was covered with a thick layer of foam, like an uninvited guest. These bubbles not only affected the uniformity of the adhesive but also caused breaks and defects during coating. Each cleanup and restart meant doubled costs and time losses.

This was no accident but a recurring challenge on many production lines. The presence of foam disrupted smooth processes and even became a source of quality risks. Until one day, the technical team introduced Chemi Tech’s defoamer, specifically designed for starch adhesives.

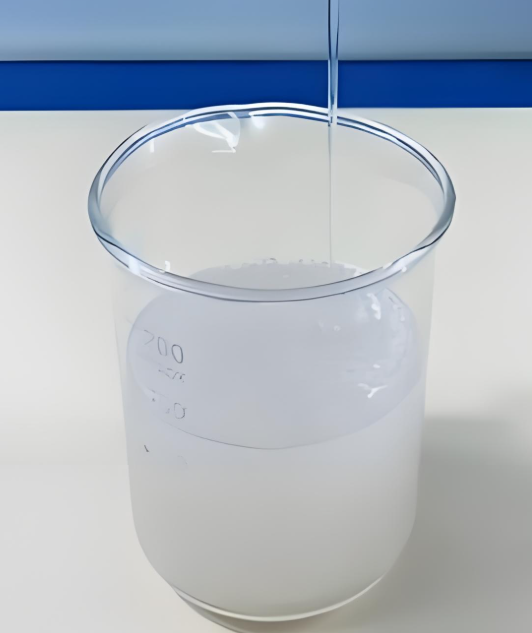

The arrival of this defoamer quietly changed the game. It penetrates bubble films with precision chemical action, destabilizing foam without compromising the adhesive’s bonding performance or film-forming quality. After addition, the adhesive becomes fine and uniform, the coating process runs smoothly, and production efficiency significantly improves. Engineer Li noted that not only were foam issues controlled, but the end product also demonstrated greater reliability.

The advantage of Chemi Tech’s defoamer lies in its deep understanding of materials science and iterative practice. Developed for the characteristics of starch systems, it quickly adapts to varying temperatures and pH environments, providing continuous defoaming and foam suppression. Whether during mixing, transfer, or coating, it silently safeguards every step of production.

Now, the production line has returned to its usual rhythm, the smooth surface of the adhesive reflecting the metallic glow of the equipment. Engineer Li can finally focus on more critical process optimizations—foam is no longer a cause for anxiety.

Guangzhou Chemi Tech New Material Co., Ltd.

Address : No. 3 Road, Lanshan Village, Xiancun Town, Zengcheng District, Guangzhou City

Contact : +86-19820415595(Manager Fang)

Tel : +86-13414362583(Manager Lee)

E-mail : crystal@gzchemitech.com