-

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE -

-

Phone number+86-13414362583

-

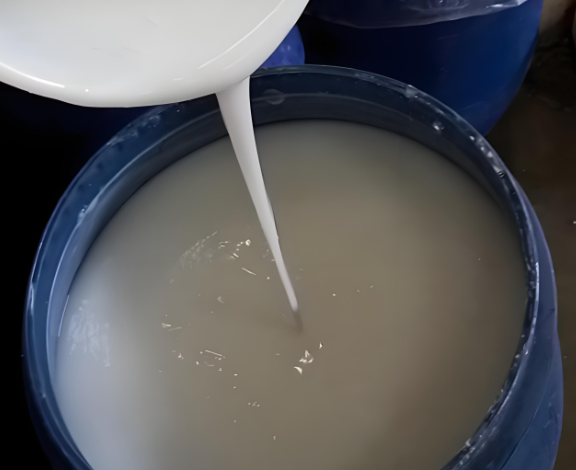

Foam formation during adhesive production and application leads to critical defects: surface irregularities, reduced bond strength, and visible voids after curing. Conventional defoamers often suffer from poor compatibility, limited persistence, or adverse effects on transparency.

Chemi Tech addresses these challenges with tailored defoaming technologies designed for adhesive systems. Key advantages include:

1. System-specific compatibility – Customized molecular structures for epoxy, polyurethane, and acrylic bases ensure seamless integration;

2. Rapid foam collapse – Modified polysiloxane compounds penetrate bubble membranes instantly during mixing and coating;

3. Zero compromise on end-product properties – Eliminates haze, cratering, or mechanical degradation.

An electronics adhesive manufacturer faced recurring customer complaints due to microfoams in cured products. After analysis, Chemi Tech recommended defoamer model KM--520 at 0.3% dosage, achieving:

- 85% reduction in mixing foam during production

- Coating surface smoothness improved to Ra≤0.1μm

- No visible bubbles after curing

This client has maintained stable orders for over 2 years.

We recommend a three-step evaluation process:

① Lab-scale compatibility tests (25℃/50℃ environments);

② Dynamic stirring simulation of production conditions;

③ Cross-section microscopic inspection post-curing.

Chemi Tech offers free samples and technical support. Contact us for customized solutions.

Guangzhou Chemi Tech New Material Co., Ltd.

Address : No. 3 Road, Lanshan Village, Xiancun Town, Zengcheng District, Guangzhou City

Contact : +86-19820415595(Manager Fang)

Tel : +86-13414362583(Manager Lee)

E-mail : crystal@gzchemitech.com