-

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE -

-

Phone number+86-13414362583

-

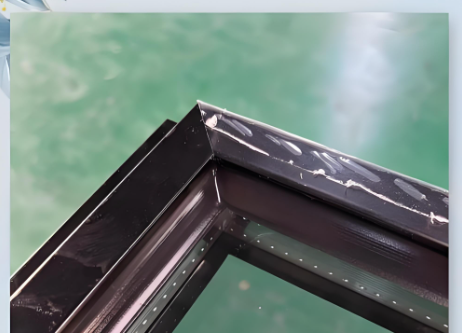

Bubble formation has long been a challenge in the production and application of glass sealants and adhesives. These bubbles not only compromise appearance but also reduce sealing performance and mechanical strength, leading to client dissatisfaction. The market demands efficient and stable defoaming solutions that adapt to various process conditions while maintaining long-lasting foam inhibition.

To address this, Chemi Tech has developed specialized defoamers for sealant systems. With unique molecular design, these defoamers rapidly penetrate and rupture bubble membranes while preventing new foam formation. Their low surface tension and high compatibility ensure uniform dispersion without affecting transparency or mechanical properties.

The solution involves three steps: First, add 0.3%-0.8% defoamer during production with thorough mixing. Second, combine with vacuum degassing to improve efficiency by approximately 40%. Third, allow settling before application to prevent bubble regeneration.

One manufacturer struggled with persistent bubbles in high-transparency silicone sealant. After implementing Chemi Tech's customized solution, bubble occurrence reduced to below 0.5% while maintaining clarity. Product yield increased to 98.7%, with cost savings of about RMB 200 per ton.

Chemi Tech offers comprehensive R support and technical services, providing tailored defoaming strategies based on client materials and processes. We provide samples and technical guidance to ensure optimal results.

Guangzhou Chemi Tech New Material Co., Ltd.

Address : No. 3 Road, Lanshan Village, Xiancun Town, Zengcheng District, Guangzhou City

Contact : +86-19820415595(Manager Fang)

Tel : +86-13414362583(Manager Lee)

E-mail : crystal@gzchemitech.com