-

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE -

-

Phone number+86-13414362583

-

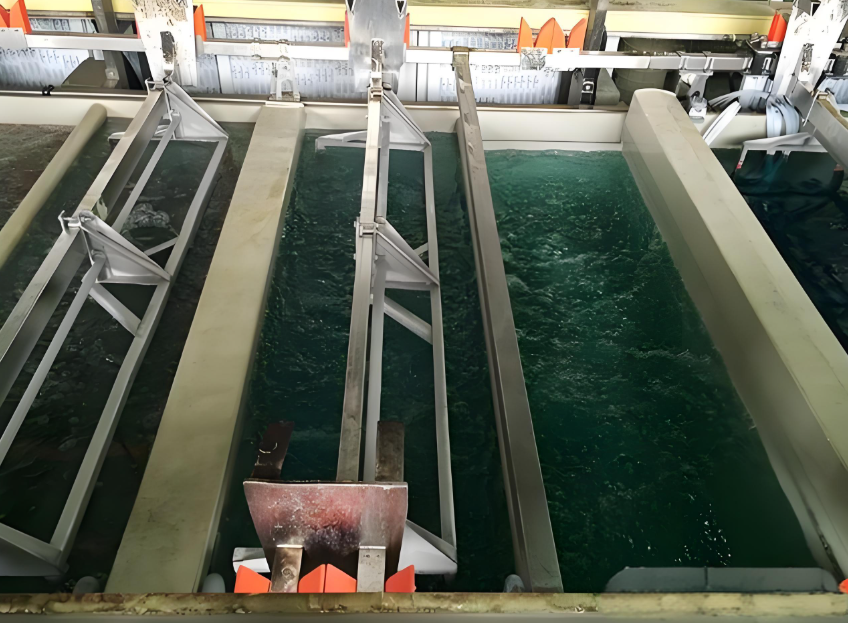

In industrial penetrant applications, excessive foam causes uneven penetration, product defects, and reduced efficiency, directly impacting production quality and costs. Chemi Tech specializes in developing and producing defoamers for penetrants, offering efficient and stable solutions to foam challenges in high-surfactant systems.

Market Pain Points & Needs

Persistent foam during penetrant use leads to tank overflow, uneven coating, or measurement errors. Conventional defoamers often fail or leave residues, affecting downstream processes.

Chemi Tech Solutions

1. Customized Formulation: Combining silicone and polyether technologies, we create compatible defoamers resistant to acids/alkalis, rapidly breaking and suppressing foam.

2. On-Site Application Support: Technicians test foam characteristics and adjust dosage methods to fit process requirements.

3. Long-Term Stability: Products maintain performance under high temperature and shear, preventing foam recurrence.

Case Reference

A metal treatment enterprise faced foam overflow in penetrant tanks, causing material waste and downtime. Chemi Tech recommended KM-464 series defoamer at 0.1%-0.3% dosage, achieving 95% immediate foam suppression and enhancing tank stability.

Chemi Tech defoamers are widely used in metalworking, textile dyeing, and more, helping enterprises improve quality and efficiency. Free samples and technical support available to address foam issues precisely.

Guangzhou Chemi Tech New Material Co., Ltd.

Address : No. 3 Road, Lanshan Village, Xiancun Town, Zengcheng District, Guangzhou City

Contact : +86-19820415595(Manager Fang)

Tel : +86-13414362583(Manager Lee)

E-mail : crystal@gzchemitech.com