-

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE -

-

Phone number+86-13414362583

-

In industrial processes, challenges such as particle agglomeration, uneven dispersion, and rapid sedimentation frequently compromise product quality and production efficiency. Traditional dispersion methods often suffer from unstable effects, short duration, or high costs. Addressing these pain points, Chemi Tech leverages years of technical expertise to develop a range of high-performance anionic dispersants, delivering practical solutions for clients.

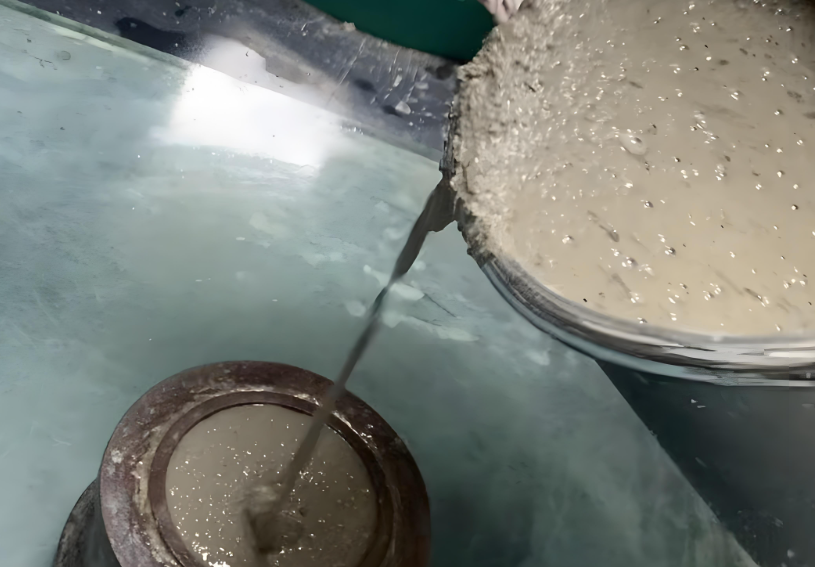

Anionic dispersants work by adsorbing onto particle surfaces through active groups, creating electrostatic repulsion and steric hindrance to prevent re-agglomeration and maintain long-term stability of dispersed systems. Their applications span various fields including coatings, ceramics, and mineral processing.

Chemi Tech's approach involves a four-step process: First, analyzing customer material properties and process conditions; second, screening suitable dispersant types and conducting lab-scale tests; third, optimizing formulation ratios for enhanced dispersion; and finally, providing guidance and follow-up support for production-scale application.

A ceramics slurry manufacturer experienced issues with viscosity fluctuations and inconsistent solid content when using conventional dispersants. After adopting Chemi Tech's tailored anionic dispersant, slurry stability improved significantly, with a 20% reduction in viscosity and a 15% increase in production efficiency, while reducing waste rates caused by quality variations.

We prioritize customer needs, continuously improve product performance, and offer end-to-end technical collaboration to help every user achieve more efficient and cost-effective production goals. For more technical details or sample requests, please contact the Chemi Tech team.

Guangzhou Chemi Tech New Material Co., Ltd.

Address : No. 3 Road, Lanshan Village, Xiancun Town, Zengcheng District, Guangzhou City

Contact : +86-19820415595(Manager Fang)

Tel : +86-13414362583(Manager Lee)

E-mail : crystal@gzchemitech.com