-

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE -

-

Phone number+86-13414362583

-

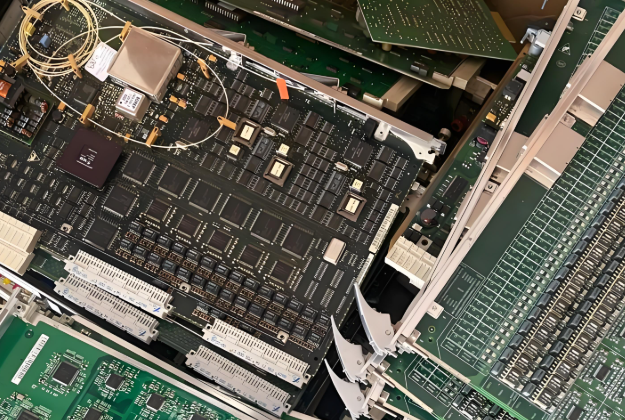

Foam formation during PCB manufacturing remains a persistent technical challenge for engineers. Surfactant accumulation in electroplating solutions causes foam-related defects including coating voids and circuit line breaks, while conventional defoamers often suffer from poor persistence or adverse effects on chemical activity.

Chemi Tech addresses these pain points with its specialized KM-218 series PCB defoamer. Utilizing polyether-modified silicone technology, this product delivers both rapid bubble breaking and sustained foam suppression. Its molecular structure specifically targets gas-liquid interfaces without compromising chemical stability of processing solutions.

Application case: An electronics manufacturer experienced persistent foam during pattern plating, resulting in approximately 3% monthly production loss due to line width deviations. After adding 0.3% concentration of KM-218 defoamer, foam completely dissipated within 15 seconds with no recurrence over 72 hours of continuous operation. Line precision deviation improved from 8μm to under 2μm, while chemical consumption reduced by 12%.

Implementation steps:

1. Foam diagnosis: Analyze foaming stages and composition

2. Lab testing: Validate compatibility with 0.1%-0.5% concentration gradients

3. Process optimization: Establish optimal dosage and replenishment cycles

4. Performance monitoring: Track suppression with surface tensiometry

5. Standardization: Develop preventive maintenance protocols

Our technical team provides comprehensive support to ensure perfect compatibility with existing processes. KM-218 has passed multiple compatibility tests for acidic/alkaline systems and complex environments with various additives.

Guangzhou Chemi Tech New Material Co., Ltd.

Address : No. 3 Road, Lanshan Village, Xiancun Town, Zengcheng District, Guangzhou City

Contact : +86-19820415595(Manager Fang)

Tel : +86-13414362583(Manager Lee)

E-mail : crystal@gzchemitech.com