-

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE -

-

Phone number+86-13414362583

-

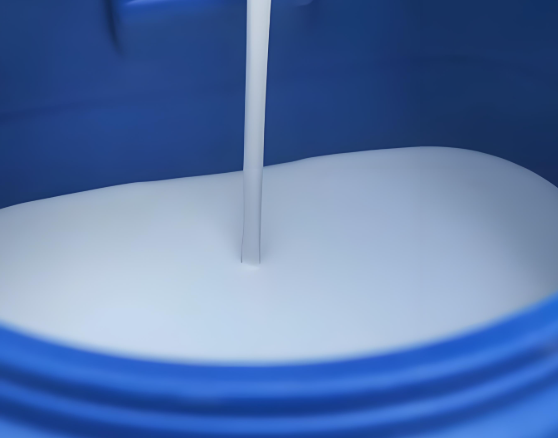

VAE emulsion often encounters excessive foam during production and application, leading to reduced efficiency, product defects, and compromised coating smoothness and adhesion. Addressing these market pains, Chemi Tech leverages industry expertise to develop specialized defoamers for VAE emulsion, delivering end-to-end support from problem analysis to resolution.

The solution process includes: First, lab foam testing to identify foam types (e.g., surface or internal foam); second, recommending suitable defoamer models like Chemi Tech KM-201 series, known for rapid bubble breaking and long-lasting suppression, based on emulsion formulation and process conditions; third, guiding small-scale trials to optimize dosage (typically 0.1%-0.5%) and evaluate impacts on transparency, viscosity, and stability; finally, providing bulk application support on production lines for consistent results.

Case study: A coatings company faced severe foam overflow during mixing and filling of VAE-based waterborne coatings, causing uneven filling and packaging waste. After on-site diagnosis by Chemi Tech's team, KM-201 defoamer was recommended. With 0.3% addition, foam was eliminated quickly, production efficiency increased by 20%, and the product showed no stratification during storage, greatly enhancing customer satisfaction.

Chemi Tech defoamers are renowned for high efficiency and compatibility, enabling low-cost, high-benefit production for VAE emulsion users. Contact us today for free samples and technical consultation!

Guangzhou Chemi Tech New Material Co., Ltd.

Address : No. 3 Road, Lanshan Village, Xiancun Town, Zengcheng District, Guangzhou City

Contact : +86-19820415595(Manager Fang)

Tel : +86-13414362583(Manager Lee)

E-mail : crystal@gzchemitech.com