-

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE -

-

Phone number+86-13414362583

-

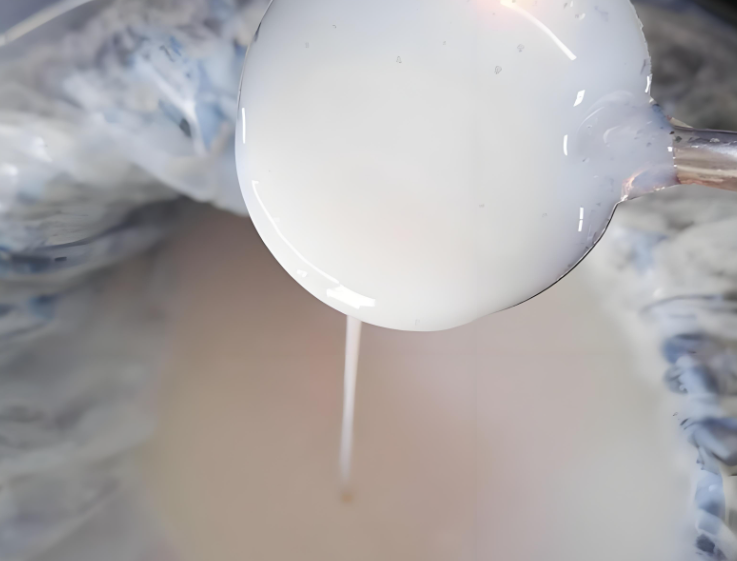

In styrene-acrylic emulsion coatings, poor leveling is a common issue leading to defects such as orange peel, craters, and brush marks, which compromise appearance and performance. To address this, Chemi Tech has developed a range of high-efficiency leveling agents that improve flow and surface tension compatibility through optimized molecular design.

Market Pain Points

Users often report compatibility issues with conventional leveling agents in styrene-aclyic systems, resulting in cratering or migration, along with insufficient stability under high-temperature conditions.

Chemi Tech’s Solutions

1. Product Selection Support: Tailored recommendations including KMP-301 (for mid-low polarity systems) and KMP-305 (high compatibility grade).

2. Dosage Optimization: Recommended dosage is 0.1%-0.5%, adjustable based on emulsion solid content and application methods.

3. Process Adaptation: Direct addition during emulsion formulation without extra emulsification steps.

Case Example

A coating manufacturer encountered persistent orange peel in water-based wood paint. Using Chemi Tech’s KMP-301 leveling agent at 0.3% dosage significantly improved surface smoothness without affecting drying time or hardness.

Application Steps

1. Add leveling agent slowly during emulsion mixing;

2. Continue stirring for 15 minutes for uniform dispersion;

3. Conduct small-scale tests before full production.

Chemi Tech’s leveling agents have helped numerous enterprises enhance product quality. Contact our engineering team for technical samples or support.

Guangzhou Chemi Tech New Material Co., Ltd.

Address : No. 3 Road, Lanshan Village, Xiancun Town, Zengcheng District, Guangzhou City

Contact : +86-19820415595(Manager Fang)

Tel : +86-13414362583(Manager Lee)

E-mail : crystal@gzchemitech.com