-

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE -

-

Phone number+86-13414362583

-

In mineral processing, challenges such as slime agglomeration, poor mineral selectivity, and inefficient equipment operation persistently affect production efficiency. These issues lead to fluctuating concentrate grades and suboptimal metal recovery rates, directly impacting economic returns.

Chemi Tech addresses these needs with tailored dispersant solutions. The approach begins with mineral composition analysis to characterize ore surface properties and slurry chemistry. Next, custom-designed dispersant molecules are engineered to selectively adsorb on target mineral surfaces, establishing an electrostatic stabilization barrier. pH and ionic strength are then optimized to enhance dispersion stability, followed by integration with flotation processes for efficient mineral separation.

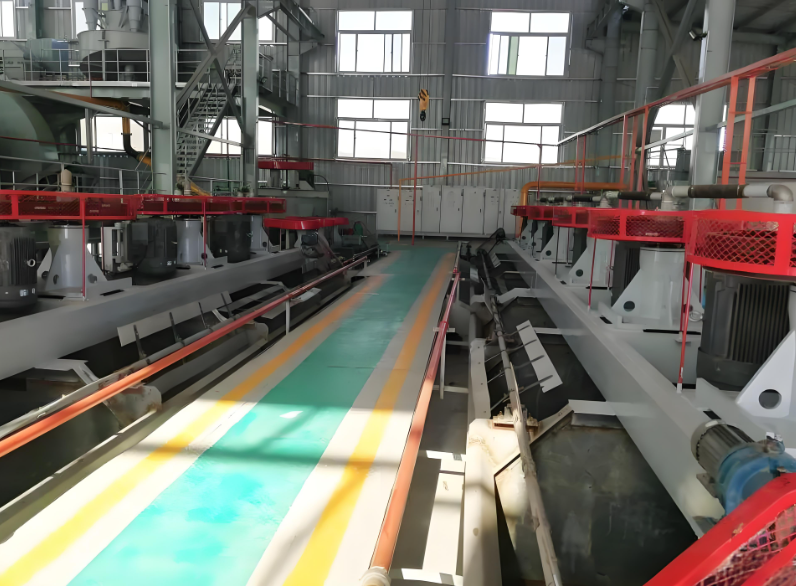

A case involved an iron ore processing plant struggling with inefficient hematite-quartz separation. Using Chemi Tech's KMK-218 dispersant series at 200g/ton ore and pH 8.5, the iron concentrate grade increased to 67.2% while silica content reduced to 4.1%. Flotation throughput simultaneously improved by 15% without equipment modifications.

We provide end-to-end technical support from lab testing, pilot trials to industrial implementation, ensuring perfect reagent-ore compatibility. Chemi Tech's solutions have been applied in tungsten, fluorite, spodumene, and other mineral processing systems, delivering cost-effective performance enhancements.

Guangzhou Chemi Tech New Material Co., Ltd.

Address : No. 3 Road, Lanshan Village, Xiancun Town, Zengcheng District, Guangzhou City

Contact : +86-19820415595(Manager Fang)

Tel : +86-13414362583(Manager Lee)

E-mail : crystal@gzchemitech.com