-

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE -

-

Phone number+86-13414362583

-

Thick-film coatings are widely used in industrial painting but often suffer from bubble defects, compromising appearance and corrosion resistance. Chemi Tech delivers scientifically-proven solutions based on decades of R&D.

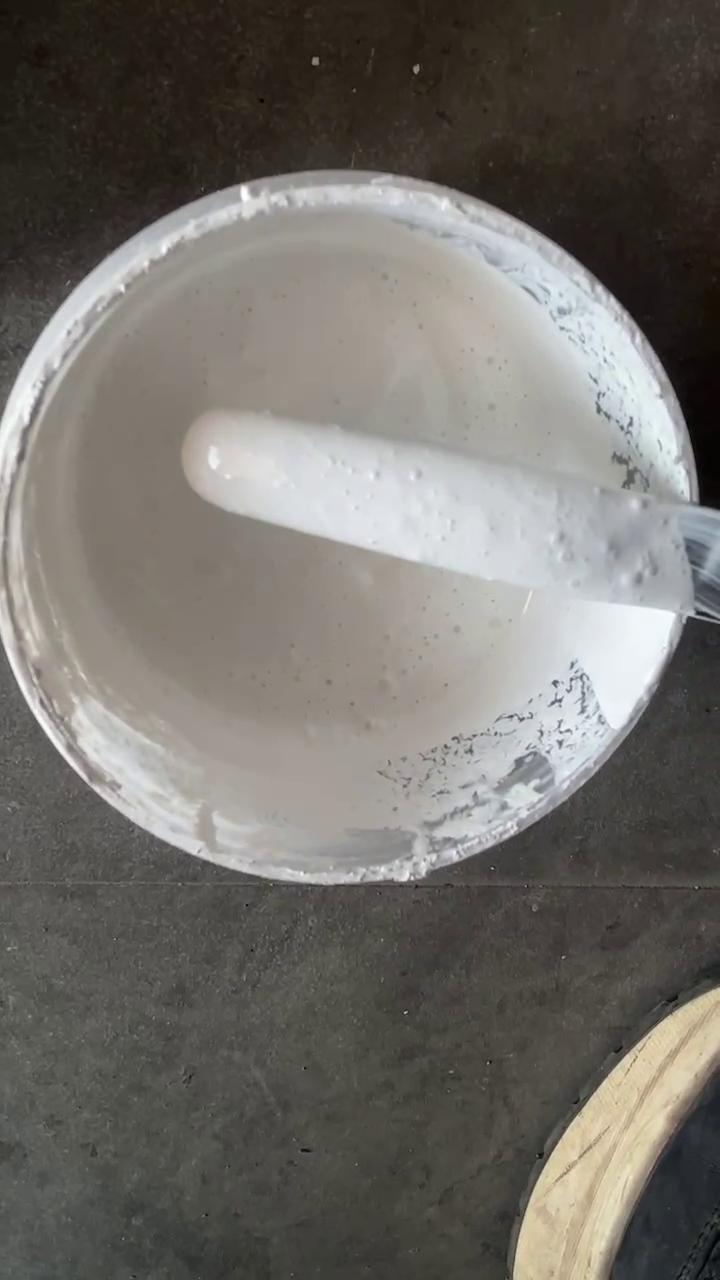

1. Air Entrapment:High viscosity coatings are prone to carry bubbles during mixing, and the bubbles are not easily broken;

2. Chemical Reactions: CO₂ release from curing agents/resin reactions;

3. Porous Substrates: Air escape from wood or concrete surfaces.

- KM-360 High-Efficiency Defoamer: Hydrophobic silica technology eliminates micron-sized bubbles instantly;

- KM-380 Long-Term Anti-Foamer: Inhibits secondary foaming during the curing stage and is suitable for systems such as acrylic acid and epoxy.

- Use low-speed mixing (<500rpm) to minimize air intake;

- Allow 15-minute bubble escape interval between layers.

-Add appropriate defoamer to quickly eliminate hidden foam in thick paste paint.

Case Study

A wind turbine blade manufacturer achieved 92% fewer bubble defects and 30% higher salt-spray resistance with KM-360.

Chemi Tech offers free technical consultation and sample testing. Download whitepapers for in-depth data at our official website.

Guangzhou Chemi Tech New Material Co., Ltd.

Address : No. 3 Road, Lanshan Village, Xiancun Town, Zengcheng District, Guangzhou City

Contact : +86-19820415595(Manager Fang)

Tel : +86-13414362583(Manager Lee)

E-mail : crystal@gzchemitech.com