-

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE -

-

Phone number+86-13414362583

-

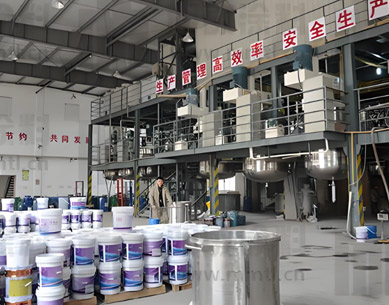

Acrylic anti-corrosion paints are widely used in industrial equipment, bridges, and steel structures due to their excellent weather resistance and protective properties. However, foam formation during application can compromise film appearance and performance. Chemi Tech’s defoamers (e.g., KM-300 series) offer an effective solution. Here’s a professional guide:

Chemi Tech defoamers are designed for water/solvent-based acrylic systems, featuring rapid bubble-breaking and long-term foam suppression.

Recommended dosage is 0.1%-0.5% of total paint weight, adjustable based on environmental conditions (temperature, humidity) and paint viscosity. Overuse may cause craters or adhesion issues.

- Pre-mixing: Blend Chemi Tech's defoamer with a small amount of base material before adding to the main paint.

- Low-speed stirring: Use a mechanical mixer (300-500 rpm) for 10-15 minutes to avoid new foam generation.

- Pre-test: Conduct small-scale trials to check compatibility.

- Storage: Keep defoamers sealed in cool conditions to prevent separation.

By following these steps, Chemi Tech defoamers can optimize paint leveling and film density, ensuring durable anti-corrosion coatings.

Guangzhou Chemi Tech New Material Co., Ltd.

Address : No. 3 Road, Lanshan Village, Xiancun Town, Zengcheng District, Guangzhou City

Contact : +86-19820415595(Manager Fang)

Tel : +86-13414362583(Manager Lee)

E-mail : crystal@gzchemitech.com