-

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE -

-

Phone number+86-13414362583

-

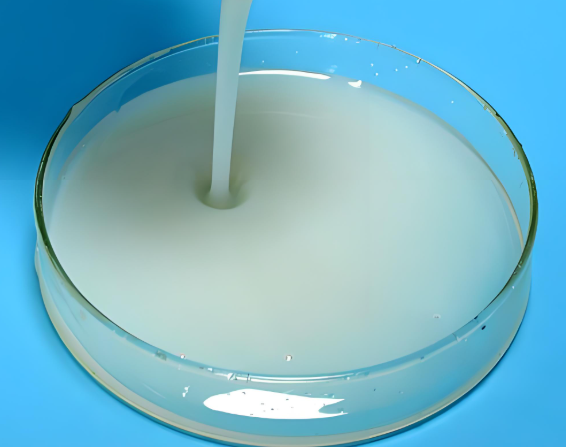

In many industrial processes, excessive foam can reduce efficiency, increase equipment wear, and even compromise product quality. Traditional defoaming methods often lack lasting effects or introduce new impurities, failing to address the root cause.

To tackle these pain points, Chemi Tech has developed a new generation of high-efficiency liquid defoamer products. Our solutions are based on in-depth research into foam formation mechanisms, utilizing composite silicone and specialized polymer technology to rapidly destabilize foam and suppress its regeneration.

The operational steps are straightforward: First, analyze the process stage and main causes of foam generation; second, select the appropriate defoamer model based on fluid properties and working conditions; third, add the defoamer in precise proportions and disperse it evenly through mixing or circulation systems; finally, monitor the foam control effect in real-time and adjust dosage as needed.

A chemical company faced severe foam overflow in its reactor production, leading to increased batch failure rates. By adopting our customized defoaming solution with the addition of KM-202 defoamer during the feeding stage, foam volume was reduced by over 90%, ensuring production continuity and saving approximately 15 hours of cleaning downtime per month.

Chemi Tech defoamers feature high chemical inertness and broad compatibility, suitable for various acid-base environments and high-temperature processes without affecting original product properties. We offer free sample testing and technical guidance to ensure precise foam resolution for customers.

Guangzhou Chemi Tech New Material Co., Ltd.

Address : No. 3 Road, Lanshan Village, Xiancun Town, Zengcheng District, Guangzhou City

Contact : +86-19820415595(Manager Fang)

Tel : +86-13414362583(Manager Lee)

E-mail : crystal@gzchemitech.com