-

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE -

-

Phone number+86-13414362583

-

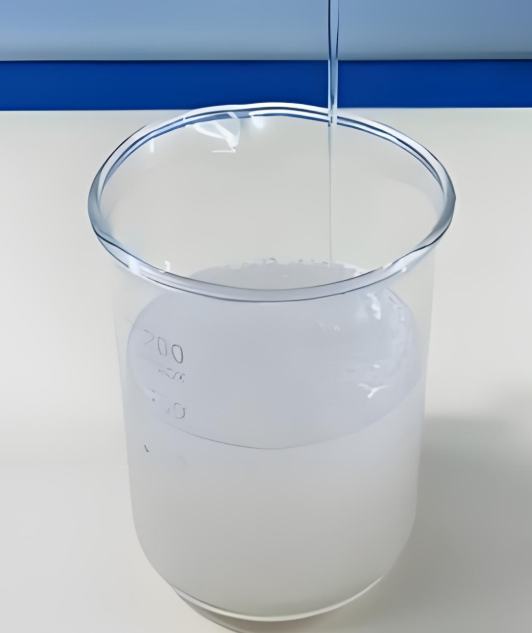

In AB glue applications, bubble problems often lead to product defects, affecting performance and appearance. The market commonly faces pain points such as low defoaming efficiency, poor stability, and insufficient compatibility. To address these needs, Chemi Tech introduces a professional AB glue defoamer, providing reliable solutions.

The solution involves three steps: First, add Chemi Tech defoamer during the mixing stage, with a recommended dosage of 0.1%-0.5% of the total formula, and stir evenly to prevent bubble formation. Second, during the curing process, the defoamer quickly breaks bubbles, reducing surface defects. Finally, post-treatment ensures a smooth and flawless product.

A case study shows that an electronics encapsulation company reduced its bubble rate from 15% to 2% after using Chemi Tech defoamer, increasing production efficiency by 20% and significantly improving product pass rates. This defoamer is compatible with various AB glue systems, easy to operate, and requires no changes to existing processes.

Chemi Tech defoamer is based on special silicone compounds, offering rapid dispersion and lasting stability, suitable for both high-temperature and room-temperature environments. Choose Chemi Tech to effortlessly tackle bubble challenges and enhance your product quality.

Guangzhou Chemi Tech New Material Co., Ltd.

Address : No. 3 Road, Lanshan Village, Xiancun Town, Zengcheng District, Guangzhou City

Contact : +86-19820415595(Manager Fang)

Tel : +86-13414362583(Manager Lee)

E-mail : crystal@gzchemitech.com