Defoamers are essential chemical additives in industrial production, designed to eliminate or suppress foam formation through physical or chemical means. Chemi Tech specializes in the development and manufacturing of defoamers, leveraging advanced component formulations and mechanisms to serve industries such as chemical processing, papermaking, and textile dyeing.

1. Key Components of Defoamers

Defoamers typically consist of active ingredients, emulsifiers, carriers, and auxiliaries:

Active Ingredients: Core components like silicones (e.g., polydimethylsiloxane), polyethers (e.g., propylene oxide polymers), and hydrophobic particles (e.g., modified silica) reduce surface tension or destabilize foam structures17.

Emulsifiers: Enhance dispersion efficiency of active ingredients, exemplified by nonylphenol ethoxylates2.

Carriers: Mineral oils or water act as mediums to stabilize and deliver active ingredients7.

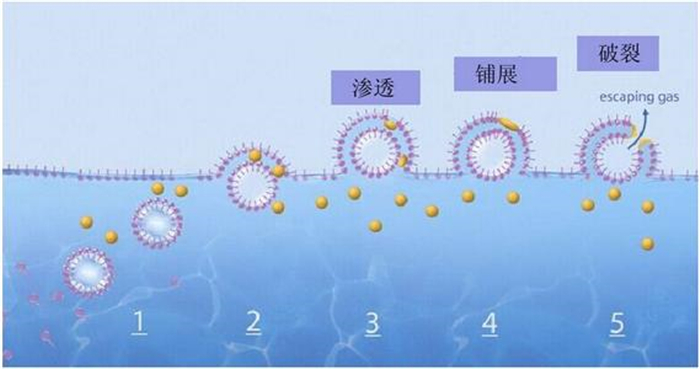

2. Mechanisms of Defoaming Action

Defoamers operate through multiple mechanisms:

Localized Surface Tension Reduction: Adsorption of defoamer molecules at bubble interfaces creates low-tension zones, causing bubble collapse due to imbalanced forces36.

Film Elasticity Destruction: Penetration into foam lamellae disrupts surfactant alignment, weakening the film's self-repair capability48.

Accelerated Drainage: Promotes liquid drainage from foam walls, leading to thinning and rupture510.

Physical Action of Hydrophobic Particles: Silica particles puncture bubble membranes, enhancing defoaming speed37.

3. Industrial Applications

Chemi Tech defoamers excel in high-viscosity systems, extreme temperatures, and corrosive environments, including:

Chemical Reactors: Control foam from gas release during reactions.

Paper Pulping: Minimize foam during pulp agitation to boost productivity.

Textile Dyeing: Eliminate bubbles in dye solutions for uniform coloration.

With optimized formulations and mechanism design, Chemi Tech defoamers deliver sustained foam suppression and rapid bubble collapse, ensuring operational stability across diverse industrial processes.

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE