-

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE -

-

Phone number+86-13414362583

-

News

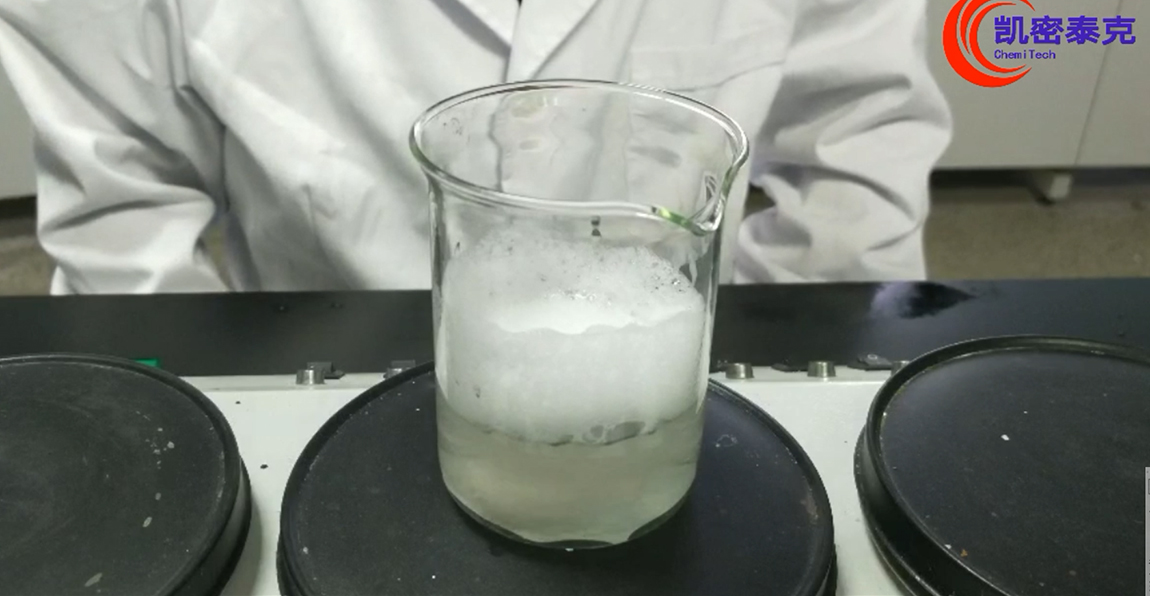

Defoamer dosage must be dynamically adjusted based on system characteristics. Chemi Tech defoamers, with scientifically formulated active components, adapt to diverse industrial challenges.

System Type: Aqueous systems require 0.01%-0.05% dosage, while oily systems need 0.1%-0.3% to counteract higher surface tension.

Foam Severity: Gradually increase dosage in high-foam scenarios, observing suppression duration for optimal adjustment.

High-Viscosity Fluids: In coatings or adhesives, pre-dilute defoamers to 5%-10% and use high-pressure injection or metering pumps to avoid cratering.

Multiphase Systems: Incorporate hydrophobic particles (e.g., silica) to enhance adsorption efficiency, reducing dosage by 20%-30%.

Automated Dosing Systems: Install foam sensors linked to metering pumps in large reactors, achieving on-demand dosing and saving 15%-20% in usage.

Dispersion Equipment Optimization: Use high-shear homogenizers (≥2000 rpm) to ensure uniform dispersion and prevent oiling or turbidity.

Guangzhou Chemi Tech New Material Co., Ltd.

Address : No. 3 Road, Lanshan Village, Xiancun Town, Zengcheng District, Guangzhou City

Contact : +86-19820415595(Manager Fang)

Tel : +86-13414362583(Manager Lee)

E-mail : crystal@gzchemitech.com