-

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE -

-

Phone number+86-13414362583

-

News

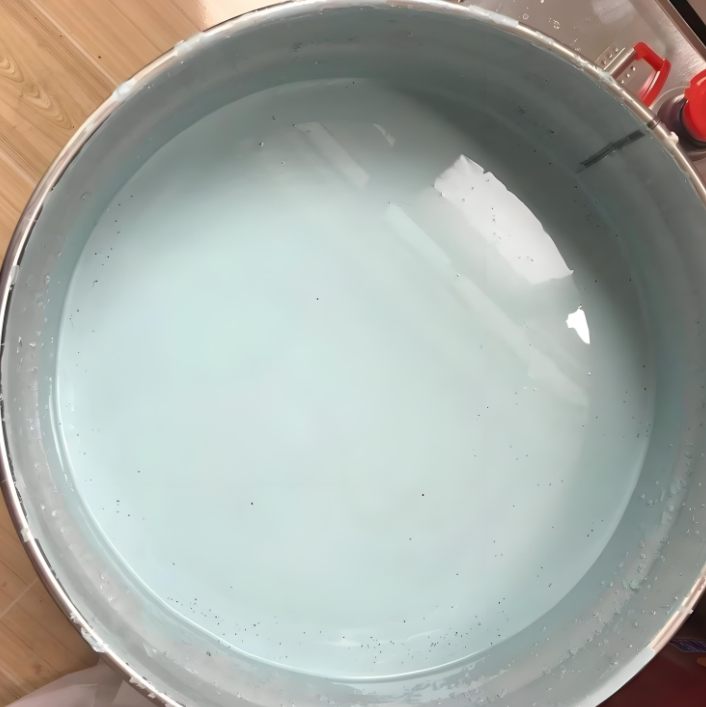

In coating applications, increased film thickness often raises defoaming difficulties. High viscosity or high-solid systems prolong bubble retention, making conventional defoamers ineffective. To address this, optimization in both defoamer selection and application techniques is critical.

Chemi Tech's defoamers for high-build coatings feature:

- Rapid Penetration: Low surface tension components quickly rupture foam walls.

- Long-Term Stability: Maintain activity in viscous systems without re-foaming.

- Balanced Compatibility: Ensure defoaming efficiency without compromising gloss or adhesion.

- Phased Addition: Add 50% defoamer during grinding, with the remainder in let-down phase for uniform dispersion.

- Stirring Control: Avoid high-speed stirring to minimize air entrapment; mid-low speed with defoamers is recommended.

- Temperature Adjustment: Optimal activity for some defoamers occurs at 25-35℃, requiring environmental adaptation.

Lab tests confirm these methods significantly reduce pinholes and craters in high-build coatings, suitable for industrial anti-corrosion or flooring applications. Small-scale trials are advised to determine optimal dosage based on specific formulations.

Guangzhou Chemi Tech New Material Co., Ltd.

Address : No. 3 Road, Lanshan Village, Xiancun Town, Zengcheng District, Guangzhou City

Contact : +86-19820415595(Manager Fang)

Tel : +86-13414362583(Manager Lee)

E-mail : crystal@gzchemitech.com