-

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE -

-

Phone number+86-13414362583

-

Orange peel and craters in high-end wood furniture coatings result in up to 15% rework rates due to surface tension gradients and poor substrate wetting. Chemi Tech’s polyether-modified polydimethylsiloxane leveling agent addresses these issues through molecular engineering:

Surface tension homogenization: Adjustable HLB polyether chains reduce surface tension below 25mN/m, achieving a spreading speed of 0.3mm/s within 3 seconds.

Matting agent orientation: Polar EO/PO segments optimize alignment, reducing the arrangement angle from 35° to 8° and improving gloss uniformity by 50%.

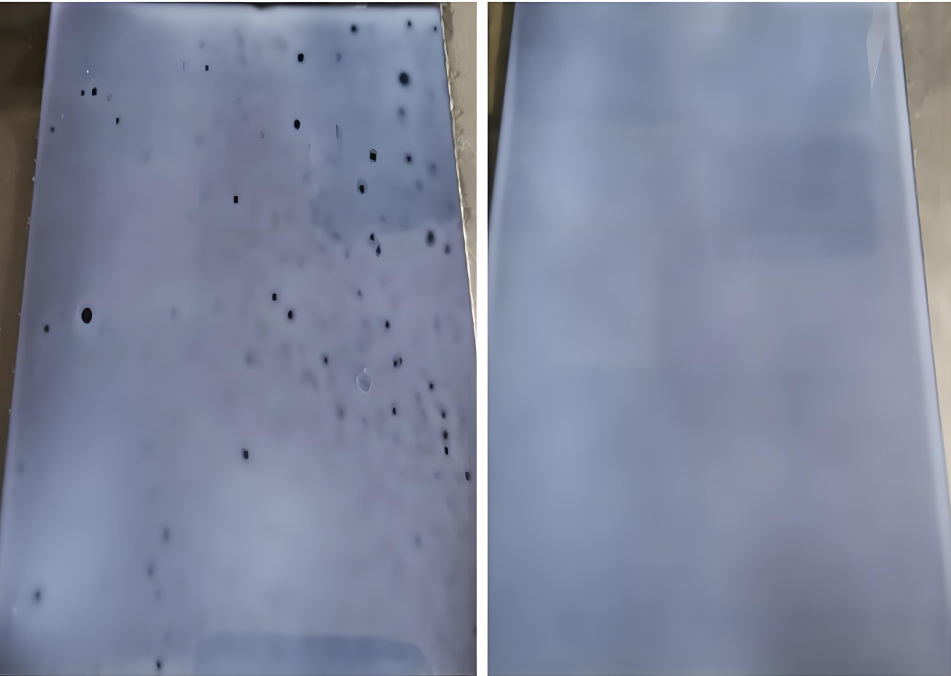

A Guangdong furniture manufacturer faced orange peel defects (>50 spots/m²) on oak cabinet panels. After adding 0.2% KMP-230 leveling agent:

Orange peel area decreased by 92%, 60° gloss increased from 85GU to 93GU;

Matting agent orientation efficiency significantly enhanced;

Annual rework costs reduced by RMB 370,000.

With amine anchoring groups for pigment affinity and fluorocarbon side chains for substrate wetting, this multifunctional additive integrates leveling, dispersion, and slip enhancement. Recommended dosage: 0.1%-0.5% for solvent-based wood coatings.

Guangzhou Chemi Tech New Material Co., Ltd.

Address : No. 3 Road, Lanshan Village, Xiancun Town, Zengcheng District, Guangzhou City

Contact : +86-19820415595(Manager Fang)

Tel : +86-13414362583(Manager Lee)

E-mail : crystal@gzchemitech.com