-

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE -

-

Phone number+86-13414362583

-

In a high-speed gearbox, Engineer Li observed persistent foam forming on the lubricant surface—the third equipment alarm this month caused by foam. Temperature spikes, efficiency loss, and accelerated wear were silently damaging the machinery. Traditional additives provided only temporary relief, while repeated dosing increased system contamination.

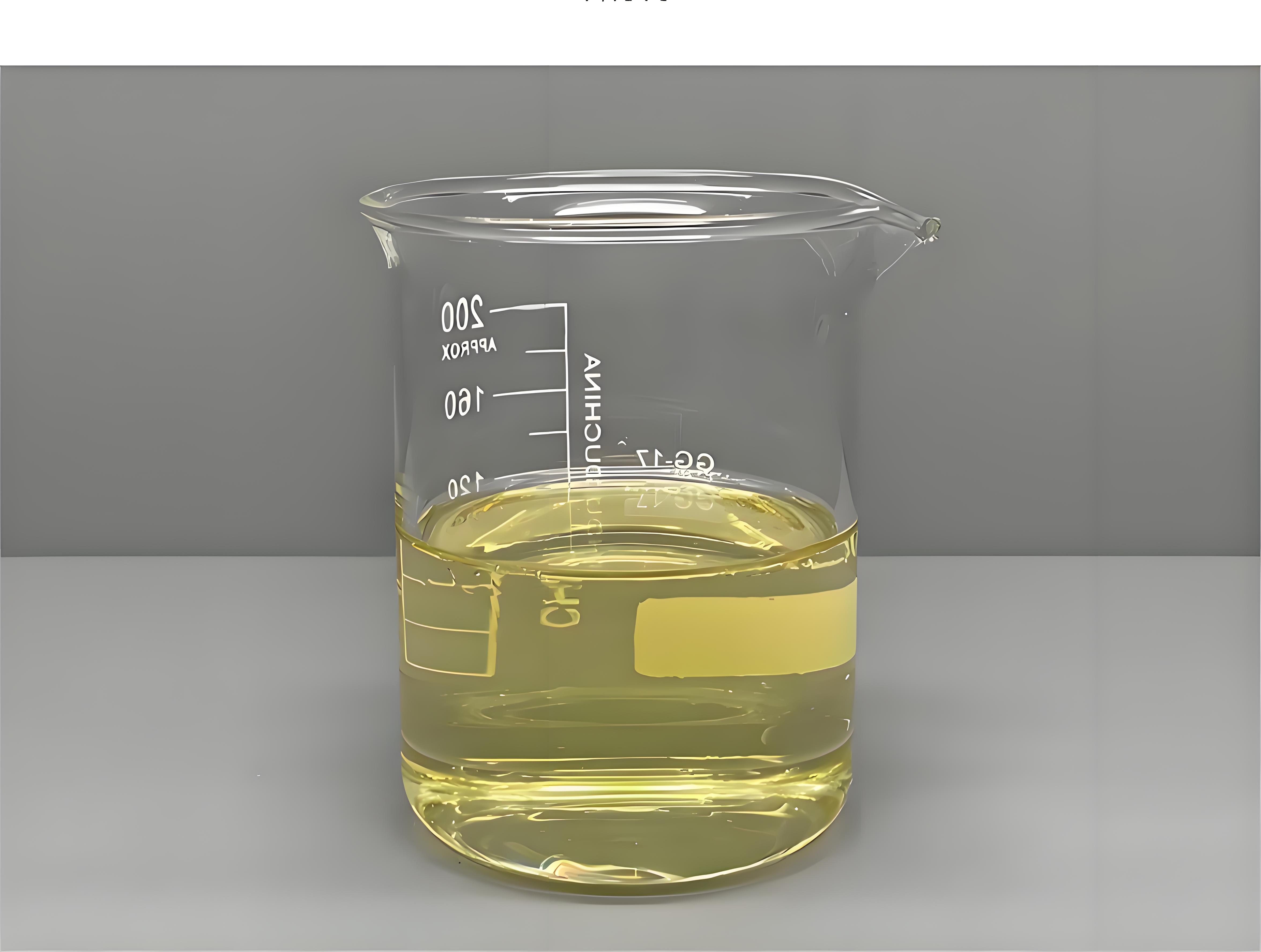

After onsite investigation, Chemi Tech's team identified that the foam originated from continuous air entrainment under extreme pressure. We developed a silicone-polymer composite system that penetrates foam interfaces rapidly, collapsing bubbles through targeted surface tension disruption.

Field tests demonstrated: adding 0.1% Chemi Tech defoamer reduced bubble volume by 98% in hydraulic systems after 300 hours of operation, bringing temperature back to safe levels. Crucially, the formula maintains compatibility with synthetic and mineral oils without separation or performance interference.

This solution now protects precision machine tools and heavy-duty transmissions alike. Every batch undergoes 7 rigorous tests including centrifugal stability and thermal endurance, ensuring consistent performance at 120°C. At Chemi Tech, we believe invisible foam protection is the cornerstone of durable equipment operation.

Guangzhou Chemi Tech New Material Co., Ltd.

Address : No. 3 Road, Lanshan Village, Xiancun Town, Zengcheng District, Guangzhou City

Contact : +86-19820415595(Manager Fang)

Tel : +86-13414362583(Manager Lee)

E-mail : crystal@gzchemitech.com