-

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE -

-

Phone number+86-13414362583

-

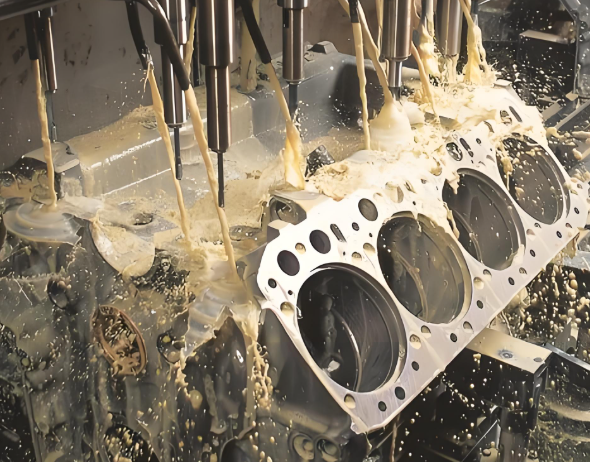

In a precision component manufacturing facility in southern China, engineers struggled with persistent foam in their cutting fluids. When high-speed machines started, foam would spill over—climbing onto guide rails, obscuring sensors, and compromising cooling efficiency. Dimensional inaccuracies and frequent equipment alarms became routine.

Then they discovered Chemi Tech’s Semi-Synthetic Cutting Fluid Defoamer.

This was no ordinary additive. Developed through advanced surface tension control technology, it employs a polyether-modified silicone compound that spreads rapidly into molecular films at the moment foam forms, destabilizing bubbles. Its micron-level dispersed particles remain active in the fluid even under high-pressure circulation.

By the seventh day of use, facility logs showed foam height reduced from 15cm to under 2cm. Tool life extended by 17%, and surface finish quality improved significantly. Most importantly, foam-related machine downtime disappeared.

The key to Chemi Tech’s effectiveness lies in its precise molecular design—compatible with various water qualities without reacting with cutting fluid components. Whether for aluminum milling or cast iron heavy-duty cutting, it works silently to maintain process integrity.

We believe real technology speaks through results. When foam troubles your process, Chemi Tech is the calm guardian in your fluid.

Guangzhou Chemi Tech New Material Co., Ltd.

Address : No. 3 Road, Lanshan Village, Xiancun Town, Zengcheng District, Guangzhou City

Contact : +86-19820415595(Manager Fang)

Tel : +86-13414362583(Manager Lee)

E-mail : crystal@gzchemitech.com