-

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE

SUPPORTERS OF CHEMICAL TECHNOLOGYDEDICATED TO A BETTER LIFE -

-

Phone number+86-13414362583

-

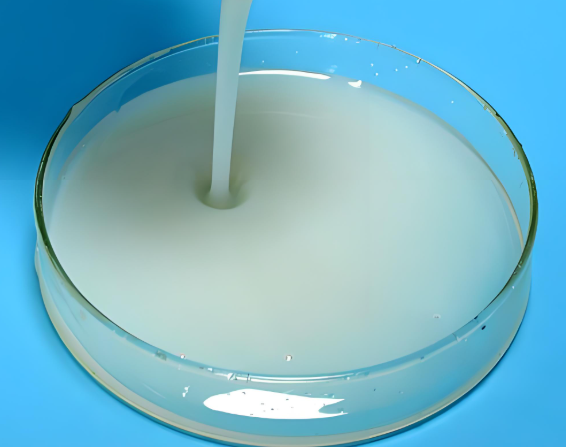

Foam formation during acrylic production significantly impacts efficiency and product quality. Excessive foam reduces effective reactor volume, prolongs production cycles, and may even cause overflow accidents. Traditional defoamers often suffer from poor stability, easy stratification, and short-lasting foam suppression, failing to meet continuous production demands.

Chemi Tech specializes in developing defoaming technologies for acrylic systems, offering high-performance defoamers with core advantages:

1. Rapid bubble breaking: Unique molecular structure penetrates bubble films within seconds

2. Persistent foam suppression: Maintains chemical stability under high temperature/pressure conditions

3. Excellent compatibility: Works synergistically with various additives without affecting product clarity

Our three-phase solution includes:

Phase I: Laboratory analysis to identify foam characteristics and formation mechanisms

Phase II: Customized dosing based on production parameters (temperature, pH, agitation speed)

Phase III: Online monitoring and adjustment to establish standardized dosing protocols

An acrylic emulsion manufacturer implementing our solution achieved 22% higher production efficiency and reduced product defect rate to below 0.3%. Their production lead commented: Consistent defoaming performance has completely resolved overflow issues during filling operations.

Chemi Tech provides full technical support with professional laboratory services for on-site foam diagnosis. Contact our technical team for customized solutions and product samples.

Guangzhou Chemi Tech New Material Co., Ltd.

Address : No. 3 Road, Lanshan Village, Xiancun Town, Zengcheng District, Guangzhou City

Contact : +86-19820415595(Manager Fang)

Tel : +86-13414362583(Manager Lee)

E-mail : crystal@gzchemitech.com